A CNC Lathe is a type of machine tool used for machining metal or plastic parts on a computer numerical control (CNC) machine. It uses rotating cutting tools to shape the piece in various angles and planes, while the piece itself is rotated around an axis. The same CNC machining lathe can be programmed to produce precise cuts in complex shapes with high efficiency. Many of the features that are available on CNC lathe machines make them very versatile in their use, allowing for a wide variety of different operations. CNC lathes are used in many industries, including automotive, aerospace and defense, manufacturing processes, as well as job shops. They are also increasingly being used in the creation of custom parts and components as well as prototyping. The use of a CNC lathe can greatly improve production time and accuracy while minimizing waste. This makes it an invaluable tool in industrial machining applications.

Overall, CNC lathes are an essential piece of equipment for any modern machine shop or factory. They offer the precision, flexibility and speed that is needed to produce parts quickly and accurately. By using computer numerical control, CNC lathes and computer controlled machines are able to create complex shapes with high accuracy and repeatability. This makes them ideal for producing small parts in a wide variety of industries.

In addition to their industrial applications, CNC lathe machines can also be used for hobbyist projects as well. By using appropriate software programs, hobbyists can program the machine to produce many intricate designs, such as chess pieces, ornaments and even toys. The use of a CNC lathe machine tools even for hobby projects can open up a whole new world of possibilities for the creative mind.

There are three different types of CNC lathes: vertical, linear axes, horizontal and multi-spindle. Vertical CNC lathes are used for large pieces of material such as steel or aluminum. Horizontal CNC lathes are used for smaller pieces such as plastics or wood, they can also be used for metal work if the machine is equipped with the right accessories. Multi-spindle lathes can be both vertical and horizontal, they can usually accommodate more than one tool at the same time and produces faster results classified as horizontal and vertical lathes. Modern CNC lathes have 3, 4, 5, or more axes systems , making them the perfect choice for machining complex geometries within a short cycle time.

In vertical lathes, the workpiece and cutting tools lie vertically, but in a horizontal lathe, they are in a horizontal position. Vertical axis CNC lathe with turning centers are used to work on heavy parts and will also have live tooling for milling on the workpiece. Horizontal CNC lathes are used for almost all generic applications. They are the most employed lathes and have a simple operation.

An ancient lathe was a symbiotic instrument, originating as far as the ancient Egyptians were concerned. While Egyptians only used two people lathes for wood-making, they are now using lathes! The traditional lathe design was upgraded to meet industry demands, such as automation. Using CNC machines Lathes can achieve extraordinary accuracy.

CNC lathe machining is a manufacturing process used by metalworking and woodworking machine shops to produce complex parts with precision. This process involves milling machines and the use of Computer Numerical Control (CNC) systems, which are programmed to control the movement of axis cnc lathes. CNC turning machines allow for the cutting and shaping of parts from materials such as steel, aluminum, brass, plastic, and wood.

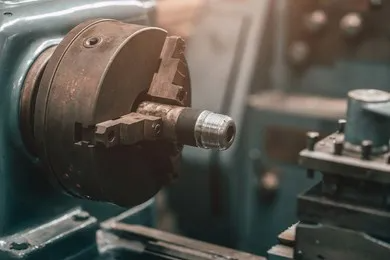

The main parts of a CNC lathe are the spindle, tailstock, bed or carriage, cutting tool holder, and fixed cutting tool or turret. The machine bed serves as the base of the machine on which all other components are mounted. Main spindle: The main spindle is made up of a spindle assembly and spindle drive system that includes motors, gears and the chuck. The tailstock holds the part in place while the main spindle part is turning and can also be used to apply pressure or drill holes. The bed or carriage supports the axis of rotation, while the cutting tool holder holds the cutting tools. Finally, the tool turret holds several different cutting tools that are used for specific operations.

The process of CNC milling machine lathe machining involves programming the CNC system with desired dimensions, shapes and cutting paths. The part is then loaded onto the machine and the programmed instructions are followed to shape it according to specification. In most cases, a single setup on the machine will produce multiple identical parts that require no additional machining or finishing operations.

A computer numerical control lathe is a machine that turns material around a central, rotating spindle, and stationary cutting tool. Your material's movement is dictated by coded instructions computer operated lathes are fed through a computer rather than operated with manual labour.

CNC-Lathe operation begins with one piece of work that has a fixed position an internal screw on the spindle assembly. When removing material from the work surface, it rotates to remove it from the surface. The CNC Lathe operates akin to a manual lathe using software that provides programming code for coding the machine's components. It can be programmed to move in various axes to obtain the exact size and form of the finished piece.

For users who are just getting started with CNC lathes, a simple machine is recommended. This type of lathe will have fewer features than a more expensive model, but it can still complete many of the same tasks. These machines usually come with easy-to-use software that allows the user to program and control the cutting process. Basic models often feature manual controls such as joystick or knobs that allow the user to adjust settings and make adjustments as needed for smooth cutting process.

Once the basics of a simple CNC lathe have been grasped, more advanced units can be used for better precision and efficiency. These machines usually feature automated tool changers, which enable them to switch between multiple tools without manual intervention. Many more manual lathes also come with additional features like automatic pallet changers, which allow the user to easily switch between multiple pieces of material when machining. Advanced CNC lathes are often used for more intricate tasks such as micro-machining and these complex machines can be much more costly than simpler models.

CNC machines rotate material in two directions and operate on two axes. Because rotations in a material are commonly called turning machines, the CNC machine tools and lathes are also commonly termed turning machines. Inside or exterior of a component are machines that use CNC machines. Internal action can affect workpieces internal diameter. A simple CNC lathe operates on two axes and moves the material it is cutting with a rotation. The material's rotation is commonly called ‘turning', so you may hear CNC lathes called CNC turning machines.

CNC lathe machines are capable of performing a variety of turning operations, such as threading, drilling, cutting and more. These machines use computerized numerical control (CNC) to program the movements of the spindle drive system. This allows for precision and accuracy in the machining process. Additionally, CNC lathes can be manually switched from one operation to the next, allowing for flexibility in machining. CNC lathes offer the capability of high speed turning and can be used to produce complex shapes with accuracy and repeatability. They are ideal for producing precision parts such as medical implants, automotive components, aerospace parts, etc. a CNC turning machine is also known as Computer Numerically Controlled Turning (CNCT) or Computer Aided Manufacturing (CAM). This technology allows the production of parts with greater accuracy, speed and efficiency. CNC lathes are used in many industries, such as automotive, aerospace and medical industries. They can be used to make complex parts with precise round shapes that would otherwise be impossible to produce with traditional machining methods. With the use of CNC lathes, operators can achieve the highest levels of accuracy with minimal scrap and downtime. This allows for faster completion of projects, as well as reduced costs. CNC lathes are the ideal choice for any manufacturing shop that requires high precision and excellent quality in their production processes.

CNC lathes offer many advantages over traditional lathes that are operated manually. The primary benefit is the ability to program complex parts using computer-aided design (CAD) software. This makes it possible to produce a large number of identical parts quickly and accurately, allowing for high levels of productivity and consistency. Additionally, CNC lathes are able to perform operations that would otherwise be impossible with a traditional lathe, tapping operations such as threading, drilling, milling and grinding. They also have the ability to produce parts with complex geometries that could not be achieved using manual operations. CNC lathes are much more efficient than traditional lathes and can help to reduce setup time, labor costs and waste. Furthermore, they require less skill and expertise to operate, making it easier for businesses to produce parts with a high level of accuracy. CNC lathes are ideal for businesses looking for an efficient and cost-effective way to produce high quality parts.

Overall, CNC lathes offer numerous advantages over traditional lathes that are operated manually. Their ability to create precise parts quickly and easily makes them an invaluable tool for businesses that need to produce complex parts in a timely manner. With their superior accuracy and efficiency, CNC lathes make it possible to achieve results that simply cannot be achieved with manual operations. Furthermore, they require less skill and expertise to operate, making them an ideal choice for businesses seeking cost-effective solutions for their production needs.