Decoding machine tools remains pivotal for manufacturing. Unravel the intricacies of CNC, lathes, and mills. The goal: give you clarity on what is CNC vs lathe vs mill. Throughout, you'll gain insights into their workings and importance. Expert knowledge ensures accurate, trusted information.

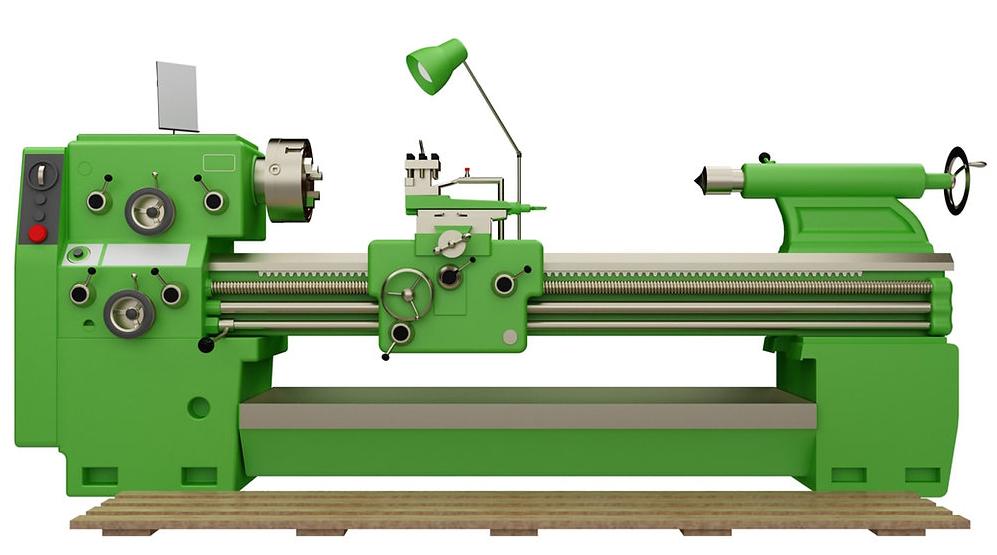

In the world of machine tools, turning implies using a lathe. Consequently, a lathe shapes material by rotating it. Tools cut away parts, leaving the desired form.

CNC, short for Computer Numerical Control, often manages these operations. A CNC lathe offers precision, guiding tools with computer-aided designs.

The act of making holes is drilling. Mills and drill presses accomplish this. Drill presses are solely for this purpose, while mills multitask. Mill drills combine the two functions. Drilling parameters include RPM (revolutions per minute) and feed rate.

Post drilling, boring enlarges holes. Lathes, especially CNC lathes, commonly execute boring. Boring tools ensure the hole diameter remains consistent. Bore depth and diameter determine the necessary tool type.

Grinding ensures a smooth finish. It removes minimal material using an abrasive wheel. Surface and cylindrical are two common types of grinders. The former smoothen external surfaces, while the latter focuses on the outside of cylindrical items.

Milling machines shape solid materials. A rotating tool cuts away material. CNC technology has revolutionized milling. Milling parameters, such as cutting speed and feed rate, play pivotal roles. Mill types include horizontal and vertical, based on tool orientation.

Shaping tools cut in linear motion. Unlike milling, shaping works on the external surface. Shapers move back and forth, cutting during one direction. Though less common than CNC mills, CNC shapers do exist. Depth of cut and stroke length are crucial parameters.

In the world of manufacturing, precise cutting is crucial. CNC machines ensure exactness up to 0.0001 inches. Lathes, on the other hand, rotate workpieces. Then, the cutting tool shapes them. Meanwhile, mills use rotary cutters to remove material. All play a part in achieving precision.

For consistent high-volume outputs, rely on CNC machines. Lathes produce cylindrical parts at high speeds. Mills handle versatile operations, creating unique parts. Every tool optimizes production efficiency.

Quality matters in manufacturing. CNC technology guarantees smooth finishes. Lathes provide symmetrical finishes on cylinders. Mills create flat, angular, or irregular surfaces. All ensure top-notch final products.

Meeting specific requirements is a must. CNC systems can be programmed for intricate designs. Lathes excel in crafting rounded custom components. Mills, conversely, are adept at diverse custom shapes. Tailored solutions are always within reach.

Consistency ensures brand trust. CNC ensures identical component production every time. Lathes recreate similar cylindrical pieces. Mills reproduce exact specs repeatedly. Quality remains uniform across batches.

Durability equals cost savings. CNC machines reduce wear through efficient operations. Lathes and mills, built with high-grade metals, promise long life spans. Proper maintenance extends their operational years. All contribute to long-term financial prudence.

Modern factories depend on CNC machines. These machines use digital instructions. Furthermore, they transform materials into finished products. Such automation increases production rates. In turn, businesses gain productivity and efficiency.

CNC devices work with extreme accuracy. In fact, most have a precision of 0.005 inches. Such precision ensures quality products. Additionally, materials are hardly wasted. High precision results in better products. Thus, customer satisfaction soars.

CNC machines rely on advanced software. Programs guide the machine's actions. CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) are common tools.

With them, intricate parts can be manufactured. Skilled operators input these programs. The result: flawless execution of complex processes.

Advanced CNC units move in multiple directions. For instance, the 5-axis CNC can maneuver five ways simultaneously. Such movement lets machines carve complex shapes. Manufacturers can thus create diverse parts. A singular machine handles various tasks with aplomb.

Manufacturers value consistent results. Fortunately, CNC machines deliver here. Once programmed, these devices produce identical items. Whether making 10 or 10,000 units, consistency reigns. Production lines, therefore, maintain uniform quality standards.

Human error has a cost. However, CNC minimizes such risks. Digital instructions guide the process. Manual interventions are limited. With fewer human interventions, error rates drop. Production processes become streamlined. Therefore, output quality remains consistently high.

Speed is an undeniable CNC advantage. The integration of software and hardware boosts efficiency. Consequently, machines quickly produce numerous parts. Reduced operation times translate to market-ready products sooner. Manufacturers, thus, meet market demands promptly.

Traditional tools have limitations. However, CNC devices break boundaries. Intricate designs become feasible. The digital precision aids in crafting elaborate patterns. Industries, from automotive to jewelry, benefit. The age-old design barriers simply vanish.

In the world of manufacturing and fabrication, understanding "What is CNC vs lathe vs mill?" becomes essential. CNC stands for Computer Numerical Control. This technology operates complex machinery through computer inputs. On the other hand, a lathe machine spins material around a central axis.

A tool then shapes the spinning material. Unlike the lathe, a mill machine cuts material in specific directions. Both lathes and mills have their distinct roles in manufacturing. Precision, efficiency, and design dictate their applications. Remember, the machinery's nature, purpose, and components determine its usage.

The headstock of a lathe is critical. Found on the machine's left end, it houses the main spindle. Motors inside the headstock make the spindle turn. Consequently, the material attached to the lathe rotates.

Positioned opposite the headstock, the tailstock offers support. Especially for longer materials, it ensures stability. Primarily, the tailstock moves along the machine bed, catering to different material lengths.

Supporting the cutting tool, the carriage plays a significant role. As the workpiece spins, the carriage moves. Its linear motion, parallel to the machine bed, determines the material's depth and shape.

Without the chuck, securing the material to the lathe becomes impossible. This component tightly grips the workpiece. Typically, chucks have three or four jaws, adaptable to various material sizes.

Above the carriage lies the tool post. Here, different cutting tools get attached. By adjusting the tool post, you determine the tool's position concerning the workpiece. Such adjustments are crucial for accurate cuts.

For a lathe's automated operations, the feed rod becomes indispensable. Running parallel to the lathe bed, this rod controls the carriage's motion. The consistent movement ensures uniform shaping of the workpiece.

Positioned atop the carriage, the cross-slide allows perpendicular movement. By moving the cutting tool closer or farther from the workpiece, it controls the cut's depth. Mastery of the cross-slide is vital for intricate designs.

Mills transform solid materials into desired shapes. Imagine a machine. Now, picture that machine cutting, drilling, and shaping items. Mills do that job! Mills have been vital in industries. From making simple parts to complex components, mills achieve accuracy. CNC, lathes, and mills play critical roles.

Each has a distinct function in shaping and producing parts. Acquiring knowledge about them empowers one to make informed decisions in industrial operations. Precision, speed, and efficiency underscore their importance. Let’s delve deeper.

In milling, orientation matters. Horizontal mills have cutters side-mounted. Vertical mills? Their cutters stand upright. Different orientations enable various machining tasks. Horizontal ones excel in deep cuts. Verticals are great for detailed surface projects.

Spindles, vital in milling, hold the cutting tools. Horizontal mills have a horizontal spindle. Vertical mills sport vertical ones. Spindle designs determine the machine's cutting direction. Spindles impact both efficiency and precision.

Holding tools securely is a must. Tools in a mill need stability. Without solid tool holding, errors can arise. Tool holders differ between horizontal and vertical mills. Each type demands specialized holders. These holders ensure optimum tool performance.

Size dictates capability. Larger mills handle bigger projects. Smaller mills focus on detailed tasks. Horizontal mills tend to be bulkier. Vertical ones might be more compact. However, always check specifications before choosing.

Rigidity ensures stability. A mill’s rigidity affects precision. Greater rigidity results in precise cuts. Horizontal mills, with their design, often provide superior rigidity. Still, advances in technology have also enhanced vertical mill rigidity.

Time is of the essence. Speed plays a pivotal role in productivity. Faster operations lead to increased output.

Speed depends on multiple factors, including the machine's design and power. Both horizontal and vertical mills have speed variations. Always consider operation speed when assessing a mill's capability.

In a lathe, your workpiece rotates. In a milling machine, the cutting tool revolves. Both manipulate different axes.

On a lathe, tools get placed against the rotating workpiece. Conversely, mills position their tools above or to the side of the non-rotating piece.

Lathes typically perform simpler tasks, often limited to rotations. Mills handle intricate profiles and patterns. Complexity varies between them.

Lathes tend to stretch lengthwise, taking up linear space. Mills require width and height, making them bulkier.

Mills dominate here. Their toolsets adapt for a variety of tasks. Lathes remain constrained, typically to rotational cutting.

Lathes excel in symmetrical objects with precision. Mills offer detailed accuracy on multiple surfaces. Precision defines their core function.

Setting up lathes is relatively quick. With mills, time increases due to tool and axis changes. Time is a factor.

Due to constant contact, lathe tools wear out faster. Mills, using varied tools, distribute wear, thus lasting longer.

Lathes, being simpler, demand lesser training time. Mastering mills requires extensive hours due to their versatile operations. Knowledge is paramount.

Both machines necessitate regular upkeep. However, lathes, with fewer moving parts, often demand lesser attention compared to mills.

Lathes quickly produce cylindrical parts. Mills take longer, especially for intricate designs. Speed varies based on design complexity.

CNC machines incorporate computer systems. Through digital integration, such machines receive instructions directly. Direct communication results in smoother operations and fewer errors. Digital pathways dictate machine movements accurately.

CNC ensures precision up to 0.001 inches in most cases. A minute error margin enables the creation of intricate designs. Traditional manual machines can't match such precision. Every cut, turn, and drill remains exact.

CNC machines excel at handling complex paths. Lathes and mills operate based on G-code instructions. These codes guide the machinery to follow intricate patterns and paths. Achieving such complexity manually would be near impossible.

Consistency defines CNC machines. Execute a task once, and the system stores the details. Then, reproduce the exact same task multiple times without variations. The products remain identical in every production cycle.

Before CNC, operators constantly adjusted machines. Now, with CNC integration, manual interventions diminish significantly. Once you input the required parameters, the machine undertakes the job. Such automation accelerates production and minimizes errors.

Wear and tear affects every tool. CNC machines recognize these subtle changes. They compensate by adjusting the tool's position. Such automated adjustments ensure the product remains within the specified dimensions.

CNC systems constantly monitor machine status. Parameters like spindle speed, tool position, and feed rate stay under constant surveillance. Real-time data gets displayed on screens. Operators can intervene if discrepancies emerge, ensuring top-notch quality control.

CNC machines possess significant storage capabilities. Store thousands of different programs within their systems. Switching between tasks becomes seamless. Need to reproduce a design from two years ago? Retrieve the stored program, and the machine recalls every detail.

|

Feature |

Definition |

Benefits |

Lathes Application |

Mills Application |

Industry Trend |

Number Example |

|

Digital Integration |

Incorporation of computerized controls |

Streamlined Operations |

✓ |

✓ |

Rising |

95% CNC adoption |

|

Enhanced Precision |

Improved accuracy of tool movement |

Less Waste & Higher Quality |

±0.0005 inch |

±0.0005 inch |

Standard |

±0.01mm tolerance |

|

Complex Paths |

Ability to create intricate designs |

Greater Product Versatility |

Advanced contours |

3D designs |

High Demand |

50+ path patterns |

|

Repeatable Jobs |

Consistent reproductions |

Time & Cost Efficiency |

1000+ duplicates |

1000+ duplicates |

Essential |

99.9% consistency |

|

Fewer Manual Tasks |

Automation reducing human intervention |

Safety & Efficiency |

Auto-feed |

Auto tool change |

Adopted widely |

70% labor reduction |

|

Tool Compensation |

Automatic adjustment for tool wear |

Continuous High Quality |

Tool life extended |

Optimal cuts |

Advanced CNCs |

±0.001 inch adjust |

|

Real-time Monitoring |

Immediate feedback & system analysis |

Prevention of Errors |

Live tool stats |

Progress tracking |

Essential |

10ms feedback rate |

|

Program Storage |

Ability to store machine programs |

Quick Changeovers |

100+ programs |

200+ programs |

Growing storage |

5GB typical storage |

Determine the desired outcome of the machining process. For intricate parts, a CNC (Computer Numerical Control) machine provides precision. For cylindrical objects, opt for a lathe. Meanwhile, for flat or irregular shapes, a milling machine serves best.

CNC machines, due to their high-tech nature, often come at a steeper price. Lathes, especially manual ones, might be more cost-effective. Milling machines can vary in price based on features and capabilities. Allocate funds wisely, taking into account future requirements.

Lathes typically have a longer footprint. CNC machines, depending on their complexity, may demand specialized spaces. Milling machines can sometimes be compact, yet their accessories might need additional room. Always measure your workspace before acquisition.

If producing large quantities in a short time, CNC machines excel. Lathes can handle repeated tasks efficiently. However, milling machines might be slower for high-volume production but are perfect for detailed, one-off items.

Different materials need specific machines. While lathes can handle metals like aluminum or steel, some CNC machines tackle even harder materials. Milling machines, with the right tooling, can work on diverse materials from plastics to heavy metals.

Mastering CNC machines necessitates software knowledge and hands-on experience. Lathes, especially manual ones, need skillful hands and an understanding of rotational mechanics. Milling machines require knowledge of cutting paths and tool selection.

CNC machines, being tech-driven, have higher upkeep costs. Lathes, with fewer electronic components, might have lower maintenance expenses. Milling machines fall somewhere in between, with costs varying depending on the model's complexity.

Mastering the realm of machine tools like CNC, lathes, and mills underpins modern manufacturing excellence. You've delved into the heart of what is CNC vs lathe vs mill mechanisms, applications, and distinctions. For advanced solutions and further expertise, consider visiting CNCYANGSEN. Navigate your machinery needs with confidence and authority.