When it comes to expanding your manufacturing capabilities or replacing outdated equipment, purchasing a used CNC machine can be an attractive option. To ensure you make a wise investment, it's crucial to conduct a thorough inspection before purchasing a used CNC (Computer Numerical Control) machine. CNC machines are a big investment, even when purchased second-hand, and inspecting them properly can save you from future headaches and unexpected repair costs. A detailed inspection helps you understand the machine’s current condition, its maintenance history, and whether it can meet your needs without significant additional investment. Purchasing used equipment offers significant cost savings compared to buying new machines. However, it also comes with risks such as hidden damages, outdated technology, and potential for frequent breakdowns if not checked correctly.

This guide will provide you with a comprehensive checklist that covers everything from the physical condition of the machine to its operational capabilities and legal documentation. This will ensure that you make an informed decision, balancing cost benefits against potential risks. By following this checklist, you’ll be better equipped to select a used CNC machine that offers reliable performance and value for your money.

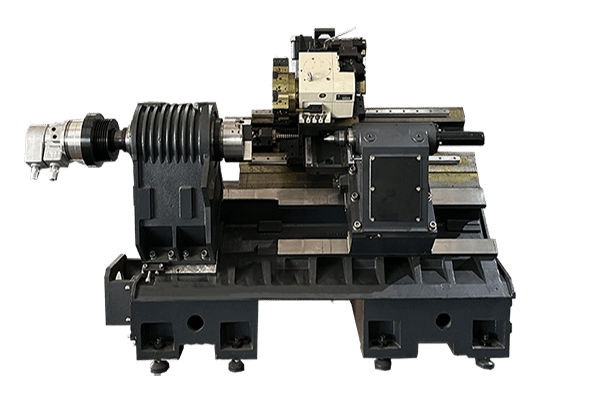

CNC machines, standing for "computer numerical control" are automated tools that shape and fabricate parts from materials like metals.

These versatile machines use various methods such as plasma cutting, laser cutting, milling, routing, and lathe operations, controlled via a digital interface to produce items in different shapes and sizes.

Purchasing a used CNC machine is a strategic decision for many business owners looking to enhance their workshop's productivity without the high costs of new equipment.

Here are some reasons to consider a used CNC machine:

● Cost Efficiency: Buying used reduces initial investment costs, making it financially less burdensome.

● Testing Viability: It allows businesses to test the machine's effectiveness in their operations before committing to a new, expensive model.

● Proven Performance: Used machines often come with a track record of performance, giving insights into their reliability and maintenance needs.

By choosing a used CNC machine, businesses can strategically manage their budgets while still improving their operational capabilities.

This step-by-step guide will help you understand each phase of the inspection process, ensuring you can make an informed decision. Follow these steps to thoroughly assess a machine's condition, functionality, and value.

Here are the detailed steps to guide you through this important process:

When you start looking for a used CNC machine, it's important to know about the different types available. Each type of CNC machine has specific uses, and understanding these can help you choose the one that best fits your needs.

CNC lathes are used to make parts by spinning them and using cutting tools to shape the material. These machines are commonly used for creating detailed cylindrical or spherical parts.

CNC milling machines use rotating cutting tools to remove material from a workpiece. They can perform a variety of operations like drilling, tapping, and slotting. Milling machines are versatile and suitable for creating complex shapes and features.

CNC routers are similar to milling machines but are mostly used for cutting wood, plastics, and softer metals. They are ideal for creating decorative designs and complex patterns.

CNC grinders use an abrasive wheel to achieve a very fine finish or precise dimensions on a part. They are typically used for finishing surfaces and sharpening tools.

CNC plasma cutters use a plasma torch to cut through electrically conductive metals such as steel, stainless steel, and aluminum. They are known for their ability to cut quickly and with precision.

Each type of CNC machine offers different capabilities. Before inspecting, consider what you need the machine to do. For example, if you need to make intricate parts in metal, a CNC lathe or milling machine might be more suitable. On the other hand, if your work involves cutting large sheets of metal or wood, a CNC router or plasma cutter would be more appropriate. Knowing the specific use and capabilities of each type of CNC machine can guide you in checking that the machine you are considering is suitable for your projects. This initial step is crucial as it sets the direction for the rest of your inspection process.

Before you start inspecting a used CNC machine, it’s important to prepare properly. This will help you conduct a thorough and effective inspection, ensuring you catch any potential issues.

Start by researching the specific model of the CNC machine you're considering. Look up the manufacturer's specifications, performance data, and any available user reviews or forums. This will give you a good baseline understanding of what to expect from the machine and what potential issues to look out for.

To properly inspect a used CNC machine, you'll need a few essential tools.

These may include:

● Micrometers for measuring small distances and checking for wear

● Levels for assessing the alignment of the machine's components

● Calipers for measuring dimensions and checking for accuracy

● Dial indicators for detecting small movements or irregularities

● Flashlights for examining hard-to-see areas

Make sure you have these tools on hand before starting your inspection.

CNC machines are complex pieces of equipment with many moving parts, and they're subject to wear and tear over time. Before inspecting a used machine, it's helpful to familiarize yourself with some of the common wear points and issues to look for.

These may include:

● Worn or damaged bearings

● Loose or misaligned components

● Leaks in hydraulic or lubrication systems

● Electrical issues or outdated control systems

● Damage to the machine's frame or housing

Taking these steps before you begin the physical inspection will put you in a strong position to evaluate the used CNC machine. You’ll be able to focus on key areas that are critical for its operation and longevity.

Now that you've done your research and gathered your tools, it's time to get hands-on and physically inspect the used CNC machine. This is where you'll really get a feel for the condition of the machine and identify any potential issues.

Here's a detailed checklist to guide you through examining each critical part of the machine:

Start by giving the machine a good visual once-over. Look for any cracks, dents, or signs of repair in the frame and housing. Check for any modifications or alterations that could affect the machine's performance or safety. Make sure everything looks straight and aligned.

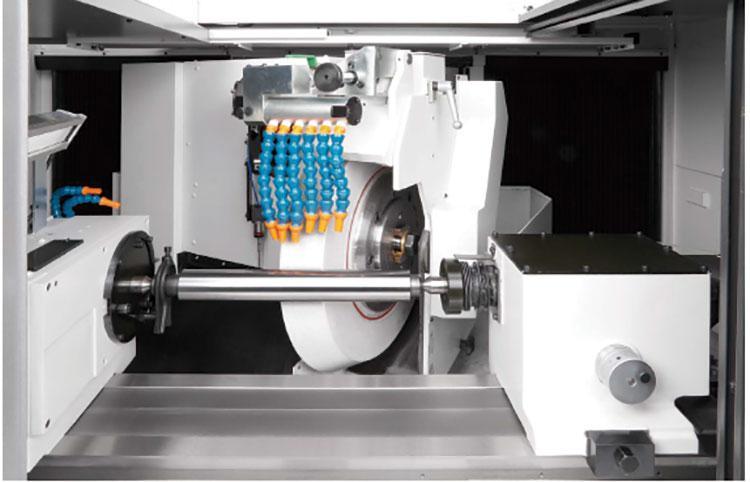

The spindle is the heart of the CNC machine, so it's crucial to check it carefully. Look for any signs of wear or damage, and check for any unusual noises or vibrations when the spindle is running. Use a dial indicator to check for any play or looseness in the spindle bearings.

Next, take a look at the tool holder and tool changer. Make sure they're in good condition and functioning smoothly. Check for any wear or damage to the tool holders, and make sure the tool changer is able to swap tools accurately and consistently.

The guides and ways are what allow the CNC machine to move smoothly and accurately. Check for any signs of wear, such as scoring or galling, on the surface of the guides. Use a level to check for any misalignment or unevenness in the ways.

CNC machines rely on complex electrical systems to function, so it's important to give them a thorough check. Look for any frayed wires, loose connections, or signs of overheating. Make sure all the switches, buttons, and controls are functioning properly. If possible, have an electrician or controls specialist take a look at the machine's electrical systems.

Many CNC machines use hydraulic systems for power and lubrication systems to keep everything running smoothly. Check for any leaks or signs of contamination in these systems. Make sure the hydraulic fluid and lubricants are at the proper levels and in good condition.

CNC machines generate a lot of heat, so they rely on cooling systems to keep everything at the right temperature. Check the coolant levels and make sure the pumps and fans are working properly. Look for any signs of leaks or damage in the cooling system components. By systematically checking each of these key components, you'll get a comprehensive picture of the condition of the used CNC machine.

Take your time, be thorough, and don't hesitate to ask questions or get a second opinion if something seems off. A little extra diligence at this stage can save you a lot of headaches down the road.

Once you've completed the physical inspection of the used CNC machine, it's time to see how it actually performs. Running some operational tests will give you a chance to assess the machine's functionality, accuracy, and overall condition in action.

Here are the key tests to conduct:

Start with a dry run, which means running the machine without cutting material. This test lets you observe the machine’s operational smoothness and whether all movements are aligned and accurate. Listen for any unusual sounds from the machine, such as grinding or clicking, which could indicate internal issues. Watch how the machine transitions between different operations and check for any hesitation or stuttering.

If the dry run looks good, the next step is to perform a test cut. This involves the machine actually cutting material so that you can evaluate its cutting performance and precision. Prepare a piece of material that is typically used with this machine and run a standard operation, such as milling or turning, depending on the type of machine. During the test cut, pay attention to the quality of the cut, the ease of operation, and the accuracy of the final product. This test will help you see if the machine can produce workpieces to the required standards.

CNC machines rely heavily on software and computer controls, so it's important to make sure these systems are functioning properly. Check that the machine's operating software is up to date and properly licensed. Run through all the control functions to make sure they're responsive and accurate. If the machine comes with any special features or capabilities, test those out as well. Operational testing is critical as it provides a practical demonstration of the machine's capability to perform the tasks for which it is intended. It helps verify that the machine not only looks good on the surface but also operates effectively and efficiently.

If the machine passes these tests, it increases confidence in its reliability and value as a purchase.

When testing the used CNC machine, it's important to also review its documentation and history. This will give you a better understanding of how the machine has been used, maintained, and repaired over its lifetime.

Here are the key things to look for:

Ask the seller for any available records on the machine, including:

● Service and maintenance logs

● Repair records and receipts

● Original manufacturer's documentation and manuals

● Any available warranty information

These records can show if the machine has had any major issues in the past, which could affect its longevity and performance.

It's crucial to make sure that the seller actually owns the machine and has the right to sell it. Ask for proof of ownership, such as original purchase receipts or titles.

Check that the machine complies with any relevant legal requirements, such as safety standards or environmental regulations. You don't want to get caught up in any legal issues down the road.

Find out if the machine is still under any kind of warranty or service agreement. If so, determine whether those agreements will transfer to you as the new owner. Even if the machine isn't under warranty, it's worth asking about any extended service plans or maintenance agreements that may be available. These can provide some added peace of mind and protection for your investment. A machine with a well-documented history of regular maintenance and careful use could be a more attractive investment. If the seller is unable or unwilling to provide important records, that may be a red flag.

After completing your thorough inspection and testing of the used CNC machine, it's time to evaluate the overall value of the used CNC machine. This final assessment will help you decide whether the machine is a worthwhile investment based on its condition, performance, and the costs involved.

Here are some key factors to consider:

Consider the condition of the machine against the asking price. Is the price reasonable for its current state? Compare it with the cost of similar models, both new and used, to determine if you are getting a good deal. Factor in any immediate repairs or upgrades the machine might need. If these additional costs are high, they might offset the savings from buying used.

Think about the logistics involved in getting the machine to your facility. CNC machines are typically large and require professional handling and transportation. Calculate these costs and consider the complexity of installing and integrating the machine into your existing setup. Ensure you have the necessary space and infrastructure to accommodate the machine. Additionally, consider the support and training you might need to operate the machine effectively. If the machine uses software or controls that are different from what your team is accustomed to, you might need additional training or technical support. By carefully weighing these factors, you can make an informed decision about the purchase. A used CNC machine can be an excellent investment, providing significant cost savings and valuable capabilities to your operations. However, it's important to ensure that the total costs, including any hidden expenses for repairs, transport, and setup, are within your budget and that the machine will reliably meet your needs.

Inspecting a used CNC machine is a crucial step in making a smart investment for your business. By following the essential checklist we've outlined in this article, you'll be well-equipped to assess the condition, capabilities, and value of any used machine you're considering.

By taking the time to thoroughly inspect a used CNC machine, you can make an informed decision that balances cost, condition, and future growth potential.

Whether you're looking to expand your production capabilities or replace outdated equipment, a well-chosen used machine can be a valuable asset for your business.

Remember, investing in a used CNC machine is a significant decision that requires careful consideration and due diligence. By arming yourself with the knowledge and tools outlined in this checklist, you'll be well on your way to making a purchase that will benefit your business for years to come.