Computer numerical control is an essential technology that is used in current industries to produce precise components and finished products at higher speed.

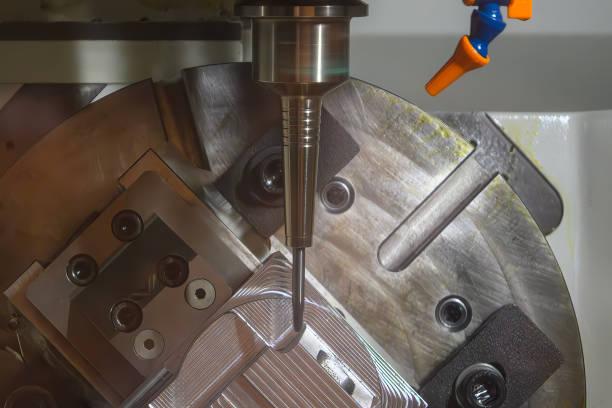

These machines use computer systems to control various tools like drills, lathes, and mills. It can produce designs of high complexity that cannot be produced when practicing the conventional method of machining.

Over time, Due to advancements in technology, different types of CNC machines have been developed to meet different demands.

Of these following machines are: 4 Axis CNC vs 5 Axis CNC machines. To gain adequate understanding about CNC Machining, it is important to understand the difference between 4 axis and 5 axis CNC machines.

Whether you are oriented in aerospace, automotive, medical industries, etc., the right decision regarding the choice of the machine has a significant impact on a considerable number of parameters of production.

CNC Machining involves using computers to control tools that are used in machining. These tools may include drillers, lathes, mills, or even a 3D printer.

It is important to note that the term “axis” means the direction in which the machine can move.

The number of axes in a CNC machine determines the machine's ability to produce complex cutting shapes.

Think of it like this: 3-axis usually means a machine that can move horizontally on the X-axis, vertically on the Y-axis, and up and down on the Z-axis. As for more axes, such as a fourth or fifth one, it promotes even more movement and variability.

Axes in CNC machines are as important as the latitude and longitude of a place. They determine how the machine reacts to movement and to cutting of materials.

The Prismatic joints provide only linear movements with respect to the basic three axes, namely X, Y, and Z.

When you include more axes, then you get rotational movements. This enables the machine to make more accurate and precise cuts.

An advantage of a 4 Axis CNC machine is that it has an extra rotary axis. The fourth axis is typically the A-axis which in turn rotates around the X-axis.

This means that in addition to translating in X, Y, and Z, it can also rotate, which allows for the machining of parts with more features.

This rotary movement affords you the flexibility of how you wish to orient and work on the material.

Increased Precision and Complexity: 4 axis cnc machines can handle a more complex model and design than 3 axis cnc machines. This makes them ideal for operations that demand accurate cutting to meet specific measurements.

Ability to Machine Complex Shapes and Features: The required rotary axis enables the machining of parts that otherwise cannot be machined using the 3-axis.

Improved Efficiency: Minimising the process of having to move the workpiece around means that the time spent and accuracy is optimised. This may also reduce the time taken to produce a product and the chances of making mistakes.

Limitations in Machining Certain Geometries: They are still somewhat limited as compared to 5 Axis CNC machines but are more capable than 3-axis machines. A few shapes and angles are still inaccessible.

Potential Increase in Setup Time and Costs: The most elaborate setups often require the spending of more funds and more time to prepare for the actual set up. This can be disadvantageous should you be coordinating lots of varied sub-projects.

4 CNC Milling, also known as computer numerical control milling, is mostly utilized in the Aerospace and automotive industries to work on parts such as turbine blades and automobile engine parts.

It is also applied in the construction of detailed wooden and metal engravings. For instance in the medical sector technology of 4-axis machines can produce intricate implants and prosthetics.

A 5 Axis CNC machine has two more rotary axis most often A and the B axis. This also gives the opportunity to the machine to turn the workpiece in several position, even more versatility.

This means that in addition to the basic X, Y, and Z translation the machine can also rotate along two different axes thus have higher degree of precision as well as complexity.

Enhanced Capability to Machine Complex and Intricate Parts: They can your part geometry no matter how complicated it is. This makes theSuitable for applications that necessitate high accuracy such as aerospace and medical manufacturing, as well as intricate mold manufacturing.

Reduction in the Number of Setups: You can machine all sides of a part at a time and this actually cuts the time taken in half. This helps to avoid the occurrence of errors and works faster when it comes to the production of large volumes.

Machine Parts from Multiple Angles and Orientations: Due to this capability, 5 5-axis machining is suitable for intricate and precision components. This will allow you to get more accurate cuts since you are close to the workpiece.

Higher Initial Cost and Maintenance Expenses: These machines are expensive, they can be costly to purchase and also the regular maintenance costs are quite high. Some of the initial costs include material costs, and it may require a large initial investment, and the operating cost also might be high.

Increased Complexity in Programming and Operation: A 5-axis CNC machine is a little more complex to control or rather to operate than a typical 4-axis CNC machine. This implies that you may be required to purchase training for the operators.

5 Axis Machining is extensively applied in some industries such as aerospace, medical, and automotive industries.

It is quite suitable for the production of various difficult pieces such as channels, aircraft equipment, medical devices, and molds. For instance, complex industries such as aerospace 5-axis machines can produce turbine blades and structures.

|

Feature |

4-Axis CNC Machines |

5-Axis CNC Machines |

|

Precision |

High but limited in geometry |

Extremely high with complex geometries |

|

Flexibility |

Good for moderately complex parts |

Excellent for highly complex parts |

|

Setup Time |

Moderate |

Low, as fewer setups are needed |

|

Cost |

Lower initial and operational costs |

Higher initial and operational costs |

|

Programming |

Less complex, easier to learn |

More complex, requires advanced skills |

|

Applications |

Aerospace, automotive, art |

Aerospace, medical, high-precision engineering |

|

Maintenance |

Easier and less costly |

More complex and expensive |

A 4-axis machining is suitable for moderately complex parts, while the 5-axis CNC is ideal for complicated and delicate parts.

Think about projects on which you mainly work and the kind of intricate work you do most often.

The money you are willing to spend should be the limiting factor, alongside the benefits that are likely to result from each machine in the long run.

Although a 5 Axis CNC machine comparison is more expensive than a conventional one, the cost could be offset in the long run by its faster set up time.

Be sure that your operators are competent enough or ensure that training is easily available.

5 Axis CNC machine is more complex than the traditional one thus there may be an added-cost of training human resource to undertake the task.

Consider what more you may require in the future. If you expect more complicated work, it is wiser to purchase the 5 Axis CNC machine in the long run.

Think of the other projects you are likely to carry out in future and if your current machine can support the projects.

Deciding between a 4-axis vs 5-axis CNC technology depends on the application that you are going to use it in. If your work includes moderately complex parts and you are operating on a budget, a 4-axis CNC machine is the way to go.

But if, for instance, your company works with highly complex parts and accuracy is a must-have, then buying a 5 Axis CNC may be more efficient.

It is always wise for one to assess his/her particular requirements and where one is in doubt, seek professional advice.

Thus, 4 Axis CNC and 5 Axis CNC machines also possess their core characteristics which make them useful for particular operations.

CNC machines with four axes as opposed to five refers to the number of controllable and affordable axes in a machine, and each type has its own advantages and disadvantages.

Thus, knowing these distinctions will help you make the right decisions in the selection of these two types of delivered applications.

Be you working in CNC Milling or in Multi-Axis CNC, the type of machinery you choose will determine your productivity and quality of the end product.