Have you ever wondered how the intricate components of modern machines and devices are precisely crafted?

Enter the realm of CNC lathe machining – a technology that combines computerized precision with mechanical artistry to shape raw materials into intricate works of engineering excellence.

In this article, we will delve into the world of the CNC lathe axis, uncovering its significance in contemporary manufacturing and unraveling the mysteries of its operation.

Without further ado, let's dive in!

A CNC lathe is like a sculptor's assistant in the world of manufacturing. It's a machine that takes digital designs and transforms chunks of raw material into finely crafted components.

But here's the twist – it doesn't just work mechanically; it's guided by computer programs that ensure every cut and movement is spot-on.

Think of it as an artist's brush, but instead of canvas, it works on metal, wood, or other materials. It's a blend of human ingenuity and technological finesse, where precision and creativity dance together.

So, when you hear "CNC lathe," imagine a masterful craftsman that brings imagination to life with stunning accuracy. Various axes are used to perform the tasks.

But what exactly are these axes, and how do they contribute to the magic of CNC lathe machining? Keep reading, and you'll know!

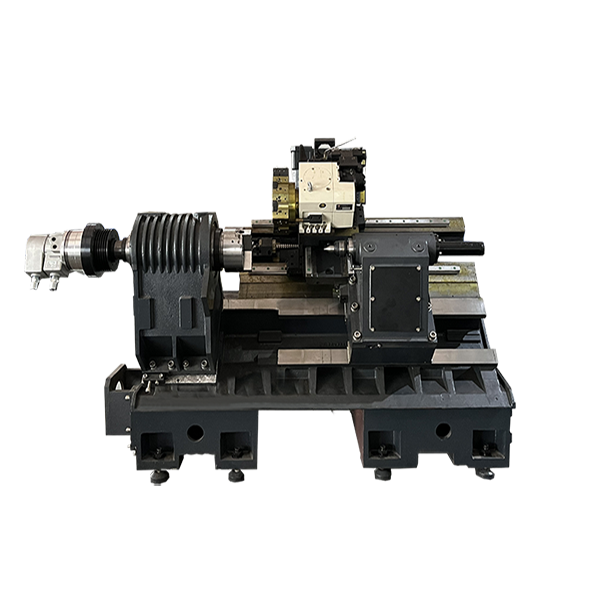

|

|

Horizontal Lathe Machine |

Vertical Lathe Machine |

But before we dive into the Axes, let's discuss the applications of CNC Lathes.

Imagine the precision required to soar through the skies. CNC lathe machines are the unsung heroes behind aircraft components, ensuring both safety and efficiency.

● Crafting Engine Mastery: CNC lathes sculpt turbine blades with impeccable precision, optimizing engine performance and fuel consumption.

● Sturdy Landings: Axles, struts, and connectors produced by CNC lathes withstand the immense stress of landings, ensuring passenger safety.

● Securing Avionics: CNC machines fashion robust housings for avionic equipment, safeguarding sensitive electronics during flight.

In the realm of healthcare, every millimeter matters. CNC lathe technology shapes medical devices with life-changing accuracy.

● Personalized Implants: Custom implants integrate seamlessly, restoring mobility and enhancing lives.

● Surgical Symphony: Precision surgical instruments ensure sterile, effective procedures that aid in healing.

● Smiles Unveiled: From crowns to orthodontic brackets, CNC precision creates dental perfection for patient comfort.

Precision propels the automotive industry forward. CNC lathes deliver components that elevate performance and safety.

● Powerful Engine Blocks: Meticulously crafted engine blocks optimize combustion, fueling driving excellence.

● Stopping Confidence: CNC precision forms brake rotors and calipers, ensuring confident, swift stops.

● Shift Smoothly: Gears and shafts shaped by CNC lathes contribute to seamless gear shifts, enhancing overall drivability.

From the heights of aerospace to the depths of medical innovation and the speed of the automotive world, CNC machines touch every facet of our lives, crafting components that drive progress, ignite innovation, and nurture human well-being.

Picture a CNC lathe axis as the choreographer of a manufacturing ballet, conducting an elegant symphony of movements that transform raw materials into finely crafted components. It's like the maestro directing an orchestra of cutting tools, guiding them precisely to carve out intricate shapes and designs.

Essentially, these axes are the GPS coordinates for the CNC machine's dance routine. Imagine telling a robot to dance, and instead of tripping over its feet, it waltzes gracefully across the workshop, creating masterpieces with a twirl.

Think of CNC machine tool axes as the master sculptors of the manufacturing world. They're like the chisel-wielding Michelangelos, except their canvas is a solid chunk of metal.

The X, Y, and Z axes bring a three-dimensional canvas to life, and it's a canvas that can turn, twist, and dive. The X-axis saunters horizontally, the Y-axis leaps vertically, and the Z-axis plunges into the material, crafting shapes that would make even Picasso nod in approval.

These axes are the navigators of a machining voyage, determining exactly where the cutting tool should go and how deep it should delve. The result? Impeccably sculpted pieces that defy human error and give perfectionist control a whole new meaning.

By the way, did you know that CNC machines with these magical axes can produce components with tolerances as tight as a hair's breadth? It's true!

They're like the superheroes of manufacturing, swooping in to save the day with their precision powers, all while keeping a sleek dance routine of movements that humankind could never replicate manually.

Let's unravel the lineup of CNC lathe axes – the rockstars of precision machining, each with their own unique moves that make crafting complex designs look like a breeze.

Think of the X-axis as the maestro of horizontal harmony. It's the one that decides how wide and shapely the cut will be. So, when you need those artistic contours or grooves on your workpiece, the X-axis swoops in, delivering that lateral charm with finesse.

Meet the Y-axis, the vertical virtuoso in the CNC lathe ensemble. Working hand-in-hand with the X and Z axes, it's like the supporting actor that knows when to steal the spotlight. When your design craves vertical adjustments for intricate details, the Y-axis takes center stage, creating those head-turning moves.

Enter the Z-axis, the master of the longitudinal journey. It's all about depth – controlling how deep the cut goes. Imagine it like a magician's wand, guiding the cutting tool as it faces off against the workpiece. This axis ensures your workpiece goes from being a solid chunk to a finely shaped masterpiece.

Ready for a twist? The C-axis is the workpiece's partner in crime, bringing the rotation game to the table. Think about it as a smooth dance partner that spins your workpiece around, making sure every angle is addressed. From milling to drilling holes around cylindrical objects, the C-axis adds that extra spin of versatility.

Say hello to the B-axis, the axis that loves a good tilt. It's like the acrobat of the CNC world, allowing the tool or workpiece to strike poses at different angles. It helps the canvas tilt, which results great and accurate cuts.

And here's a jaw-dropping stat: CNC lathes with these various axes can achieve precision within micrometers! That's the equivalent of drawing a line so thin that only a magnifying glass can see it.

Now that we've unveiled the mysteries of CNC lathe axes, let's dive into the enchanting dance they perform to bring designs to life.

Imagine the CNC system as the conductor, reading the script of programmed instructions - often in the form of G-code.

Each line of code is like a choreographer's note, guiding every move the cutting tool will make. It's like setting the stage for a masterpiece.

Before the show starts, the CNC lathe axis system takes a moment to find its rhythm. The axis motors are calibrated, like tuning instruments before a symphony.

This ensures the machine begins its performance from a known starting point, laying the groundwork for precise execution.

As the curtain rises, the CNC system orchestrates the dance of the axes. Imagine the X, Y, Z, and sometimes even C axes moving harmoniously.

If a component needs turning, the X-axis takes center stage for positioning, the Z-axis manages the cut's depth, and the C-axis gracefully spins the workpiece if needed.

During the performance, sensors provide real-time feedback. Think of them as the dancers' eyes on the stage, ensuring each move is on point.

If a step goes astray, the CNC system adjusts in a heartbeat, guaranteeing every cut is as precise as a prima ballerina's pirouette.

With the stage set, the cutting tool takes its cue and engages with the workpiece. It's like the brush touching the canvas, transforming a blank space into a work of art.

The tool moves along its axes, carving intricate shapes and designs.

Throughout the performance, the CNC system fine-tunes its rhythm. Just like a conductor adjusting tempo, it monitors and adapts feed rates, ensuring every detail is executed flawlessly.

As the final act approaches, the CNC system ensures the last moves are executed perfectly. The magic of CNC lathe axes lies in their repeatability – a promise that the same routine can be executed repeatedly, like an encore of excellence.

With applause ringing in the air, the finished workpiece emerges. The CNC lathe axis system's harmonious coordination guarantees the creation meets the desired design, like a standing ovation for precision craftsmanship.

These steps, intricately woven together, showcase the marvel of CNC lathe axis technology. It's the art of transformation, where raw materials take center stage and emerge as finely crafted masterpieces, leaving us in awe of the dance between human creativity and digital precision.

But are all CNC Lathe Machines equivalent? The answer is no! So how can you find the best one? Don't worry. Here are five key factors that can help you find that ideal dance partner in the world of CNC machining:

1. Precision Performance - Imagine a pianist hitting every note flawlessly. That's the kind of precision you want from your CNC lathe. Look for machines that boast accuracy within a few micrometers, ensuring your components have impeccable consistency.

2. Versatile Axes - Just like a dancer needs different steps for different routines, a CNC lathe needs various axes for various tasks. Opt for a machine with multiple axes, like the X, Y, and Z axes, for multidimensional creations. Some advanced ones even throw rotational or tilting axes for that extra performance edge.

3. Rapid Speeds - Time is of the essence, right? Look for a CNC lathe that can perform its moves swiftly. Machines with rapid traverse rates can move from point to point quickly, reducing overall production time. Some top-tier models can zip along at rates exceeding 30 meters per minute!

4. Cutting Tools Compatibility - Just as a dancer needs the right shoes, a CNC lathe needs the right cutting tools. Ensure the machine you're eyeing is compatible with a wide range of cutting tools, giving you the flexibility to create various shapes and designs.

5. Ease of Programming - Dancing isn't fun when the steps are too complicated to remember. Similarly, a CNC lathe should have user-friendly programming options. Seek out machines that come with intuitive software interfaces, allowing you to choreograph your machining routines without pulling your hair out.

Still not sure which one is right? Don't worry. We have some of the best CNC machines for you. Let's discover those!

YANGSEN machines are more than tools; they're the embodiment of Mr. Lin's relentless spirit and our dedication to transforming visions into reality.

With each product, we bring craftsmanship, innovation, and reliability to your machining endeavors. Welcome to a world where history, innovation, and precision converge - welcome to YANGSEN.

Here are some of our best products:

1. YSLC-500 - Best Vertical CNC Lathe Machine: Master the vertical realm with precision and finesse.

2. YSC-580 - Best Horizontal Lathe Machine: Where horizontal machining meets innovation and accuracy.

3. YST-600 - Best CNC Drilling & Tapping Center Machine: Unleash drilling and tapping prowess with cutting-edge precision.

4. YS-770 - CNC Milling Cutting Drilling and Engraving Vertical Machine: Your gateway to sculpting, cutting, drilling, and engraving with utmost precision.

5. YSM-9038 - CNC Double-Column Machine: Double the power, double the precision - setting new standards.

Explore our exceptional lineup of CNC machines at YANGSEN and witness the fusion of history and innovation in every precision-crafted piece.

Whether you're seeking vertical mastery, horizontal precision, drilling excellence, or double-column power, we have the perfect machine to bring your visions to life.Step into a realm where craftsmanship meets cutting-edge technology. Contact us today and let YANGSEN be your partner in shaping the future of machining.