The CNC tapping machine is suitable for processing high-gloss products and precision molds, and can realize the functions of drilling, milling, boring, and wringing most metal products, and can finish coordinating boring, various complicated cams, prototypes, laminating films, arc grooves, and other processings accurately and efficiently.

Max. X-axis Travel :

600mmMax. Y-axis Travel :

400mmMax. Z-axis Travel :

350mmMax Workpiece Length :

700mmMax Workpieces Width :

400mmMax Workpieces Weight :

350KGApplication :

Precision Mold, Bathroom Products, Auto Parts, Semiconductor IndustryProcessing :

Drilling, TappingCNC Tapping Machine Characteristics

|

Simplicity and efficiency by design, drilling, and tapping centers are perfect for precise, fast, and repeated machining processes. The focused drilling and tapping design maximizes the efficiency and threading speed with the ability to drill into harder materials. The CNC tapping machine is widely used in the processing of small and medium-sized housings, covers, plates, and other batch parts in industries such as high-precision molds, automobiles, locomotives, aviation, instrumentation, textile, electronic instruments, precision hardware, and machinery manufacturing. The machine bed is made of high-grade HT300 cast iron precision casting The BT30 spindle speed is 20000rpm, power of the motor is 5.5kw Equipped with 21T servo saucer tool changer, tool changer time is 1.8s Rapid displacement reaches 60/60/48, and Rigidity tapping speed is 6000rpm.

|

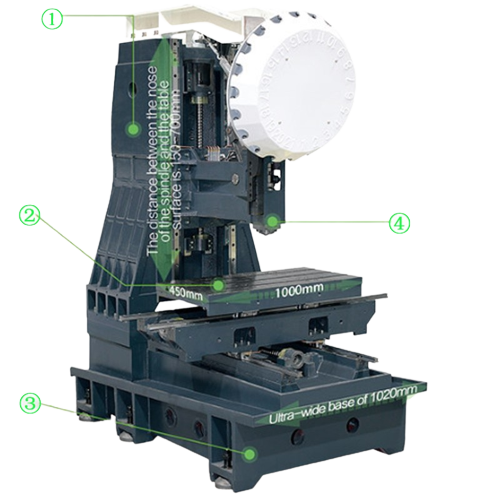

YST-600 CNC Drilling & Tapping Center Machine Characteristics

①. Higher Z-axis

The effective stroke of the Z axis is 410mm, the distance between the nose of the spindle and the table surface is 150-560mm, four axes can be installed without additional raiser blocks, and the rigidity of the machine tool is not affected.

②. Large Table

Table size:1000X450mm. The larger worktable allows bigger parts processing.

Optical linear scales

Optional Heidenhain, Fagor optical linear scales with an accuracy of under ±5um.

③. Stable Base

Shared V8 base, 1020mm span, high rigidity, high precision bed.

④. Powerful Motor

Standard 20000rpm BT30 high-speed motor, power 5.5kw; optional 12000rpm for large torque motor, power 7.5kw.

Fast tool change speed

Equipped with 21T servo tool magazine, tool change time is 1.8s; X/Y axis rapid traverse at 60m/min, Z axis rapid traverse at 48m/min.

Powerful spindle

YSV800 configuration BBT40 outer diameter 150mm with higher rigidity, and short nose spindle, five bearings, coolant nozzles.

Upgrade Configuration

German Rexroth roller linear guideway, Taiwan servo tool magazine, Taiwan spindle.

Beautiful appearance

European and American style sheet metal design, beautiful and practical.

CNC Drilling And Tapping Machine Parameters

| Model | YST-600 | ||

| Subject | Specifications | Units | |

| Travel | X/Y/Z axis | mm | 600/400/350 |

| Spindle Nose to Worktable | mm | 145-495 | |

| Spindle Center to Column | mm | 420 | |

| Three-Axis Guideway | Ball Linear Guideway | ||

| Worktable | Worktable Size (L*W) | mm | 700x420 |

| Maximum Table Load | kg | 350 | |

| T-Slot | mm | 3-14x125 | |

| Spindle | Spindle Taper | type | BT-30 |

| Spindle Speed | rpm | 20000 | |

| Spindle Drive Type | DDS | ||

| Feedrate | Rapid Traverse(X/Y/Z) | m/min | 60/60/48 |

| Cutting Feedrate(X/Y/Z) | m/min | 10 | |

| Tool Changer | Automatic Tool Changer | Fast Wheel | |

| Type of Tool Shank | type | BT-30 | |

| Tool Storage Capacity | Piece | 21 | |

| Max. Tool Diameter (Adjacent) | mm | 60 | |

| Max. Tool Diameter (Empty) | mm | 80 | |

| Max. Tool Length | mm | 200 | |

| Max. Tool Weight | kg | 3.5 | |

| Tool Change Time | sec | 1.8 | |

| Motor | Spindle Motor | kw | 5.5 |

| Three-Axis Servo Motor | kw | 1.5/1.5/3.0 | |

| Accuracy | Accuracy | mm | ±0.005 |

| Repeatability | mm | ±0.003 | |

| Power Required | Power Requirement | kva | 15 |

| Air Pressure Requirement | kg/cm² | 6^8 | |

| Others | External Dimensions (L*W*H) | mm | 2000x2650x2750 |

| Gross Weight | t | 3.6 | |

|

Safety Door

Automatic Lubricating System

Fully Enclosure Guard

|

Rigid Tapping

Heat Exchange for Electric Cabinet

Coolant Tank & Chip Tray

|

Dual LED Work Light

LED 3 Color Warning Light

Spindle Oil Cooler

|

Spindle Nose Air Blow

Leweling Bolits and Pads

M30Auto Off

|

|

Optical Linear Scale

Chip Conveyor System

|

Tool Breakage Probe

Oil Skimmer

|

Oil Mist Collector

Workpiece& Tool Probe

|

CTS

Rotary Table

|

Tags :