Embark on a transformative journey with our guide: Master your CNC projects and CNC considerations with a CNC Speeds and Feeds Calculator, an ultimate guide!

Our content assures of insights of how to attain perfect execution which leads to every detail being perfectly crafted. Prepare to investigate settings that will change the way you look at CNC settings.

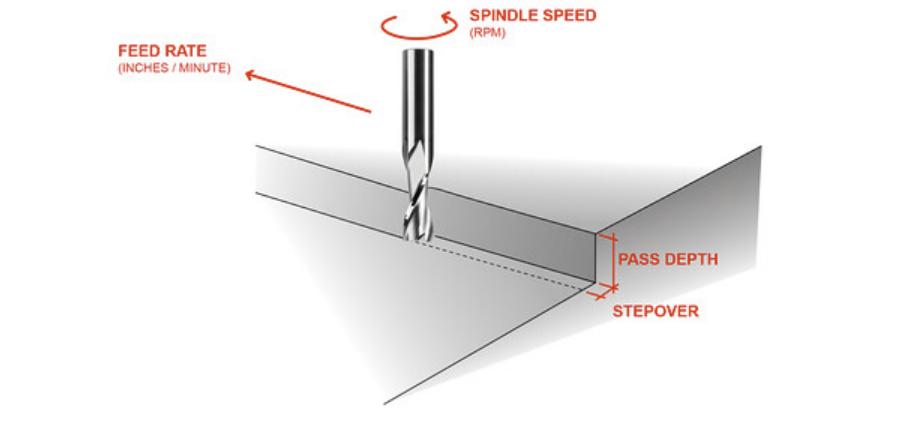

Using CNC Machine Speeds and Feeds Calculator, it’s important to take into account the tool’s RPM, which essentially defines the cutting speed. The heat speed influences the surface finish, tool wear, and part accuracy. The optimal cutting speed depends on a particular material such as aluminum which may require faster setting than steel.

Calibration of the calculator to material hardness makes cutting process optimal, eliminates unneeded tool stress, and makes it efficient. The user has to type in some specific material properties into the calculator to get accurate recommendations for the cutting speed. It minimizes mistakes and improves the production flow.

CNC Speeds and Feeds Calculator are used to determine a feed rate, which is an essential factor for machining productivity. It sets the rate at which the tool travels in the material. Good choice of the feed rate can greatly affect the quality of the cut, life of the tool, and wear of the machine.

By taking into account the diameter of the tool and the material to be machined, the calculator assist in setting the right feed rate.

The precision in these environments helps to prevent problems such as chatter, early wear of the tool, and dangerous workpiece damage, which leads to the more comfortable workflow.

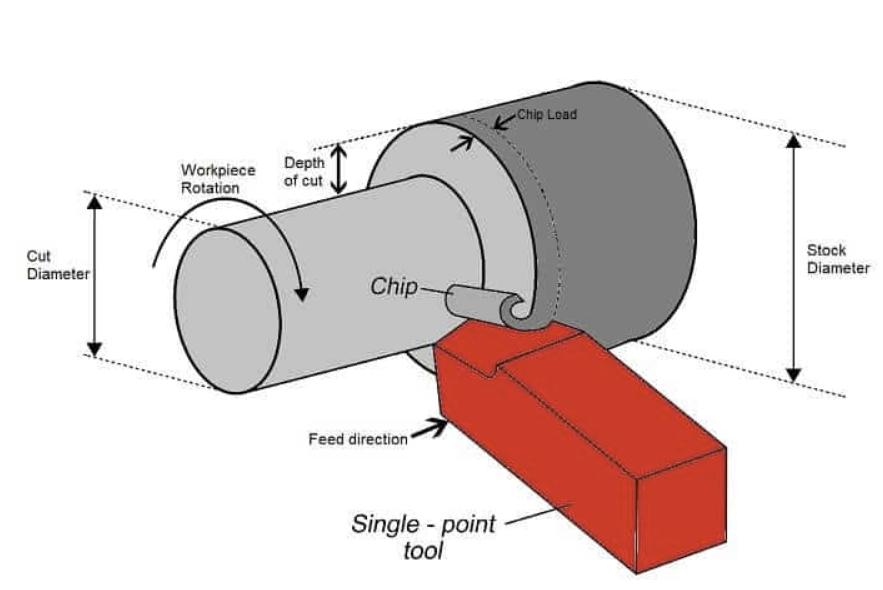

Chip load represents how much of the material that a tooth of the cutting tool removes per cycle. With a CNC Speeds and Feeds Calculator, machinists can use chip load to optimize cutting efficiency and minimize tool wear. Proper chip load settings eliminate thermal problems and tool breakage.

The calculator takes into account variables such as number of flutes, material, and cutter diameter, creating a compromise parameter that improves tool life and part finish.

Modifications are done complying with real-time observations and calculator recommendations for the better results.

The material’s removal rate (MRR) is a key variable in machining, which can be improved by the use of a CNC Speed and Feeds Calculator. However, higher MRR is likely to lead to the quicker production times but could cause the tools and machines be stressed if not properly adjusted.

The calculator helps to determine the optimal speed-efficiency compromise, considering the tool’s performance and the material properties. The operators must key in the correct data to the calculator to have the MRR maximize but without the quality and the equipment being compromised.

|

Parameter |

Units |

Importance |

Typical Values |

Factors Affecting |

Measurement |

|

Cutting Speed |

m/min (meters per minute) |

Determines surface finish, tool life |

100-300 for steel, 300-600 for aluminum |

Material, tool material, tool geometry |

Calculated from RPM and cutter diameter |

|

Feed Rate |

mm/min (millimeters per minute) |

Affects production rate, finish quality |

0.01-0.5 mm per tooth |

Tool type, material hardness, machine capability |

Directly set on CNC machine |

|

Chip Load |

mm/tooth (millimeters per tooth) |

Influences tool wear, chip removal efficiency |

0.01-0.2 mm/tooth |

Cutter diameter, number of teeth, material |

Calculated from feed rate and RPM |

|

Material Removal |

cm³/min (cubic centimeters per minute) |

Key for evaluating efficiency and power consumption |

5-500 depending on setup |

Tool size, feed rate, depth of cut |

Product of cut depth, feed rate, and cut width |

Table on Essentials of Speeds and Feeds!

The precision of input is critical in the use of a CNC Speeds and Feeds Calculator. The data about the tool geometry, material characteristics and the machining parameters, such as spindle speed and feed rate, should be precise. The machine accuracy makes the calculator to be able to give precise, correct and useful machining process settings.

Input errors can result in the wrong speeds and feeds, which can give the poor surface quality, increased tool wear, or machine damage. Hence, input checking before calculation is a good practice which has a very big influence to the success of machining operations.

Picking the correct CNC Speeds and Feeds Calculator is essential to obtain desired machining results. Different calculators provide solution to different machining operations, materials, and tool types. Alignment of a calculator with the needs of the project enhances its usability.

The influences like UI, added functionality like tool path suggestions, and versatility with various CNC machines should be taken into account. The right calculator ensures simplicity in decision-making during machining complex situations to improve overall performance and productivity.

Using a CNC Speeds and Feeds Calculator does not only reduce the setup but also improves machining processes. These calculators help to determine the optimum speeds and feeds regarding the balance between machine capabilities, tool life, and workpiece quality in particular.

Optimization results in uniform quality of the product, minimal material waste, and effective tool utilization that altogether lead to savings and improvement of operational efficiency. Usage of these calculators on regular basis is a tactical benefit in sustaining competitive manufacturing processes.

The diameter of the tool is a key input for any CNC speeds and feeds calculator. It affects the cutting speed, feed rate, and general movements of machining.

A greater diameter tool can withstand more severe cutting conditions but may require changes in speed to avoid tool deflection and ensure precision. Accurate typing of the tool diameter into the calculator allows adjusting these settings, resulting in the best tool performance and durability.

Checking the dimensions of the tool on a regular basis is important for keeping correct information.

The material type being machined very much influences the settings in a CNC Speeds and Feeds Calculator. Materials differ in properties like hardness, conductivity, and abrasive nature that determine speeds and feed rates of cutting.

Properly identifying the material type enables the calculator to recommend the most effective practices for machining, to minimize tool wear, and for better finish. Such specificity guarantees that the machine functions in an optimal environment which suits the features of the material.

Flute count is an input for CNC Speeds and Feeds Calculator and is a vital factor for the tool performance. Additional flutes enhance the strength of the tool and its material removal capabilities but also require adjustments in feed rate to prevent excessive heat and chip load per tooth.

Right setting of the flute count in the calculator allows optimizing the cutting process, making it a compromise between productivity and tool health. This modification is necessary to ensure accuracy in precision machining operations and to prolong the life of the tool.

Optimal chip size is very important for enhancing tool productivity and durability that can be estimated using a CNC Speeds and Feeds Calculator. The proper chip thickness guarantees the effective cutting without overloading the tool. It improves the heat transfer and decreases the chance of the tool being broken. Chip thickness precisely calculated assists in keeping cutting edge sharp and prolongs tool life that is essential for quality machining operations. This kind of optimization raises not only effectiveness, but also quality of prepared surface of part being machined.

Calculated speeds and feeds have a direct influence on the longevity of the tool, which underlies the necessity to employ a CNC Speeds and Feeds Calculator. Correct settings minimize unnecessary load on the tools preventing premature wear and failure.

The calculator helps to prolong the working life of the tool by optimization of feed rate and cutting speed that depends on the tool material and design. This also cuts the cost of replacements and helps maintain a constant quality of manufactured products over a long period.

A CNC Speeds and Feeds Calculator is crucial in determining the surface quality of machined parts. Correct speeds and feeds help the tool to work with the material in the best way, avoiding defects such as burrs, burns, and scratches. The optimum settings obtained from the calculator improve the visual and functional properties of the surface, which are essential for parts that require high precision and finish. Periodic corrections and adjustments using feedback and inspection results may result superior surface quality all the time.

Application of speeds and feeds as per the CNC Speeds and Feeds Calculator does a great deal to improve operational efficiency in CNC machining process. Efficient operations lead to decreased cycle time per part thus reducing the cost of production as well as enhancing the throughput.

The calculator allows setting of parameters that optimize the removal rate and at the same time minimize the machine down time that may be associated with the tool failure or the maintenance needs. The proper use of calculator makes the machining process to be economical and maintain the high quality.

The hardness of the material greatly affects the settings set out by a CNC Speeds and Feeds Calculator. Hard materials need lower speed in order to keep tool wear and to prevent damage of the workpiece.

Correct input of material hardness into the calculator makes all the parameters of machining specific to the material and this improves not only tool life but also the machining results.

So, proper knowledge and application of these parameters are important for successful treatment of different type of materials under a CNC environment.

The thermal properties of materials are very important, and they determine the speeds and feeds for CNC, which could be calculated with a CNC Speeds and Feeds Calculator.

Materials that have a very high level of thermal resistance may need lower speeds to avoid heat generate during the process of machining. Proper entry of thermal characteristics in the calculator prevents overheating which deteriorates both the tool and the material.

Such prudent management of machining parameters according to the thermal properties results in a better quality and efficiency of operations.

Materials machinability determines the ease of cutting and is one of the crucial factors used in CNC Speeds and Feeds Calculators for selecting the proper machining speeds and feeds. Materials that are easy to machine can be machined at higher speeds without sacrificing tool life or surface quality.

Entering precise machinability ratings in the calculator ensures reduced production times with high quality results. This setting is very important for improving productivity and reducing wear and tear on CNC machines.

Hardness and durability are the qualities that make carbide tools favorites and in turn influence the settings on a CNC Speeds and Feeds Calculator. Said tools are capable of taking higher speeds and feeds, thus, making possible an effective material removal.

Precise input of the carbide grade of the tool into the calculator ensures that ideal machining conditions are created which in turn prolongs the life of the tool and increases its performance.

Such exact setting results in higher performance and downtime reduction caused by tool wear or replacement.

For many machining operations, high-speed steel (HSS) variants are critical and so the CNC Speeds and Feeds Calculator requires specific configurations. Although HSS tools are multifunctional, they usually run at slow speeds compared to the latter due to poor heat resistance.

Setting the calculator properly with the HSS tool specifications helps maintain the best trade-off between the cutting speed and the tool life, resulting in the overall effectiveness of the machining process without losing the quality of the workpiece.

The flute geometry on a tool influences its cutting efficiency and is an essential input in a CNC Speeds and Feeds Calculator. The geometry of the flute plays a major role in chip evacuation efficiency, which influences heat management and tool wear.

Entering the information into the calculator correctly allows optimizing the cutting process, ensures the tool operates reliably in different cutting conditions. This results in better surface finish and longer tool life.

Rigidity of the tool influences the machining parameters set by a CNC Speeds and Feeds Calculator, and that determines the ability of the tool to resist high cutting forces. Cut quality is improved when more rigid tools work at higher feeds and speeds, reducing vibration.

Accurate representation of the tool rigidity in the calculator settings enables the use of aggressive machining strategies that reduce cycle times while still retaining accuracy and tool integrity.

Control of vibration is paramount in CNC Machining and affects the adjustments on a CNC Speeds and Feeds Calculator. The vibration minimization increases the tool life and quality of the part by eliminating chatter. By means of the calculator, the accurate calibration of speeds and feeds promotes the best damping conditions, which is a guarantee of steady tool’s work. These vibration settings are managed proactively and so, there are no future defects in the workpiece and the machinery works indefinitely.

The integrity of the tool and quality of the workpiece are directly affected by the parameters input into a CNC Speeds and Feeds calculator which is particularly important in effective heat management.

Proper settings guarantee the heat produced in the process of machining to remain within controllable ranges, thus, maintaining the sharpness of tools and preventing material deformation.

Tool and material properties based adjustments ensure high productivity without heat-related problems.

Tool wear is a big problem of CNC machining, which can be solved by adjusting speeds and feeds is the CNC Speeds and Feeds Calculator. Parameters are set to make the tool’s contact with the material optimal, reducing wear and tool life.

Continual update of these settings according to wear patterns and tool condition is critical to keeping machining process’s quality at high and reduce cost of the replacement.

The control of spindle load is very important for machine health and effective operation, which is supported by settings provided by a CNC Speeds and Feeds Calculator.

Correct spindle load settings eliminate mechanical overload and maintain a steady operation thus reducing the chances of machine failure and maintenance downtime. Correct input coupled with continuous monitoring of spindle performance and usage helps in maximizing the utilization of the machine thereby improving overall productivity and life.

In this guide, the CNC Speeds and Feeds Calculator has been an indispensable tool for learning CNC machining techniques. It brings a complete solution for cutting conditions optimization, which results in excellent project performance. Adopt the accuracy and speed it brings to your process. For more information and detailed elaboration of advanced tactics, go to CNCYANGSEN. Take your CNC projects to the next level by incorporating these vital calculations into your everyday work.