5-axis CNC machining is one of the most advanced processes available today. It uses subtractive machining technology to provide endless possibilities for part creation. This technology uses cutting tools that work on five axes to cut workpieces into the desired shape and size. 5-axis machining provides greater accuracy and precision, efficiency and reliability. The increase in the number of axes also gives five-axis milling machines better capabilities than similar products. Furthermore, the process allows for full automation and management using Computer Numerical Control (CNC). Therefore, many reliable CNC machine shops rely on this technology for their precision CNC machining services.

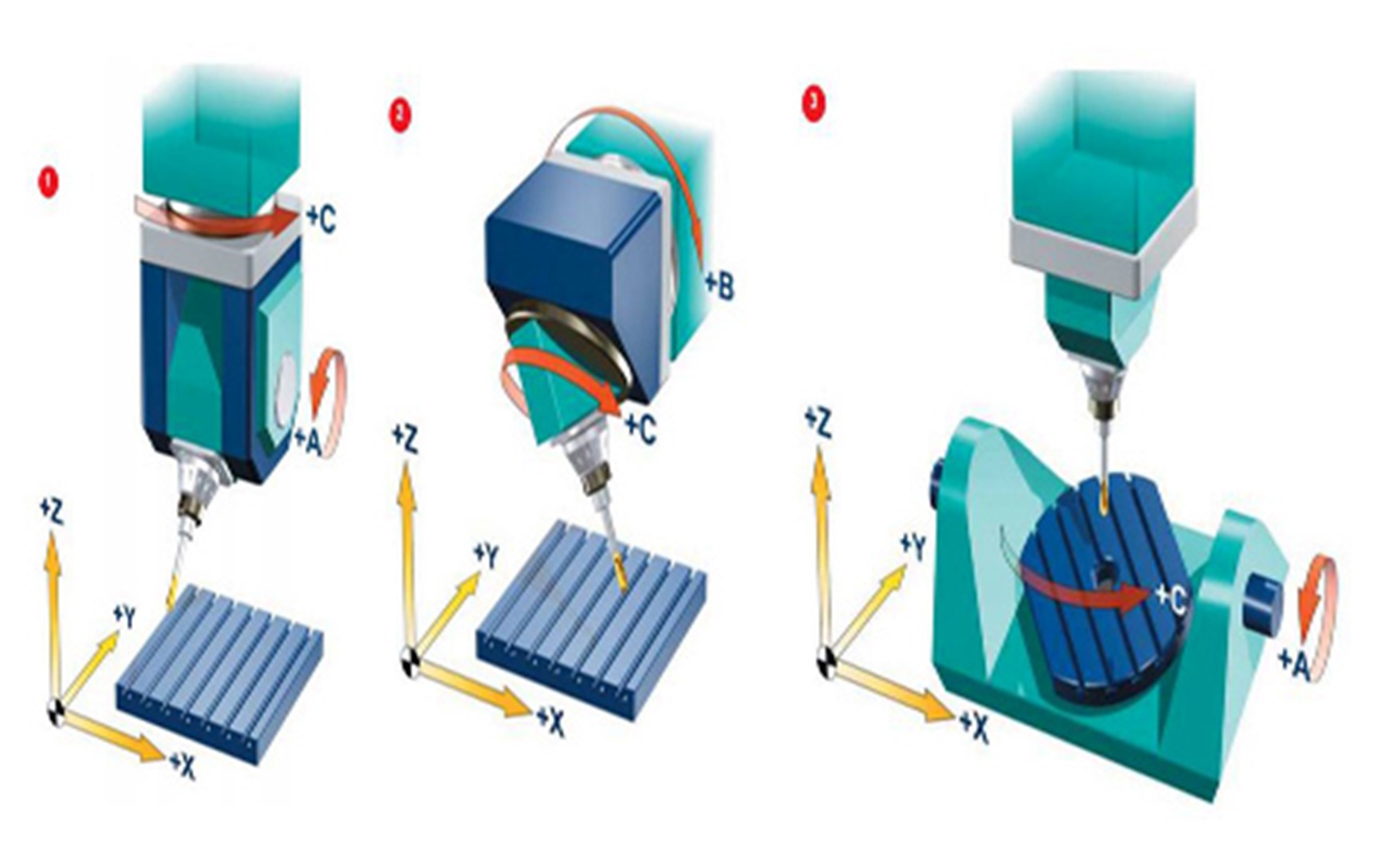

This process involves the cutting tool moving in five axes simultaneously. 5-axis CNC machines offer three linear axes and two rotary axes working simultaneously to achieve complex parts. This usually involves increasing the tilt of the table or tool, which in turn increases rotation and movement.

The 5th axis allows machinists to manufacture up to 5 faces in one operation. This makes the process very efficient and precise. It also makes it suitable for creating complex structures and features with minimal setup. With multiple parts requiring consistent machining of 5 sides, this process is becoming increasingly valuable to multiple industries.

To help understand the axes in a 5-axis CNC mill, let’s explain the importance of axis count in CNC machining. The number of machining axes is the number of directions the cutting tool (or raw material) can move to create the desired product. For example, traditional CNC machines have three axes count. Therefore, their tools can only move in the X, Y, and Z axes.

Tool movement:

Horizontally on the X axis;

The Y axis is vertical;

Move back and forth on the Z axis.

5-axis machining centers add linear axis functionality by tilting (and rotating) the table. There are two additional rotational axes, called the A-axis and the C-axis. The A-axis is also called the tilt table axis, while the B-axis is the table rotation axis. The inclusion of these axes allows for the machining of more complex geometries than is possible with 2- or 3-axis CNC machines.

Like other CNC machines, 5-axis CNC milling machines rely on computer instructions. The machine's programmed instructions control the movement of the cutting tool and the workpiece. The 5-axis machining process begins with the creation of a 3D CAD model of the desired component.

After this, the CAD model is exported to CAM software which converts it into a computer program (G-code). G-code contains the instructions for the CNC machine. It contains toolpaths created according to the required part geometry. These instructions control the movement of the cutting tool along the linear axes (X, Y, and Z). It also controls the orientation of the table along the rotational axes (A and B) to create the desired part.

This process allows machining 5 sides of a workpiece with one clamping. As a result, it saves manufacturing time and costs, helping you bring your products to market faster. Note, however, that the speed and direction of movement depends on the type and configuration of the 5-axis machine.

5-axis machines can enhance your machining programs and increase scalability. These machining centers can be of various types to meet the needs of the manufacturing industry.

The three main types of five-axis CNC machines are:

The rotation axis of the Head/Head machine is located in the head. Their 5-axis vertices sit on a platform that moves across a stationary table, holding the workpiece in place. Therefore, you don’t need to worry about tool interference on the machine tool spindle head.

This way, the vertices have a higher chance of moving around the workpiece, making it suitable for producing large, heavy parts. The machine table can bear heavy weight without affecting the accuracy of the rotating ace. However, the design of these machines limits their movement along the axis of rotation.

A head/table machine setup has one rotating axis in the head and another in the rotating table. They have a limited range of rotation axis located in the head. The rotary axis, on the other hand, has a wider range (unlimited) and is located within the table.

This setup is beneficial because it allows the workpiece to be rotated consistently without any restrictions. However, there is a limit to the number of parts it can produce. This is because the workpiece is located on a rotating axis.

In this setup, the 5-axis machine's rotational axis is located within the worktable. Therefore, all rotation occurs on the table and the head does not move. The design of these machines makes them suitable for machining undercuts. Additionally, since the cutter head does not rotate, the machinist can easily see how the cut will be made during the programming phase.

However, the machine layout is not well suited for machining large or heavy components. This limitation is due to the table's inability to support much weight.

As mentioned earlier, the movement of the axes during 5-axis manufacturing is determined by the instructions of the CNC program. There are basically two types of CNC machining operations that are suitable for 5-axis:

The working principle of the trunnion machine is that the A axis rotates around the X axis and the C axis rotates around the Z axis. The movement of the table represents the axis of rotation. That is, both rotation axes are located within the table, while the head remains stationary (table/table). Trunnion 5-axis CNC machine tools are suitable for:

Heavy workload

Removes heavy metals without moving the head

Better undercutting capability

The working principle of a rotary 5-axis CNC machine is that the B-axis rotates around the Y-axis, while the C-axis rotates around the Z-axis. This motion differs from the Trunnion style in that the table remains level throughout the entire cut. Therefore, it can support heavier components. Rotary Rotary machines are suitable for:

Machining larger components

Use shorter cutting tools

The ability to move the cutting tool and workpiece on up to 5 sides simultaneously offers several advantages to many industries. It allows for the cost-effective manufacture of complex parts.

5-axis CNC machines allow five surfaces to be machined simultaneously. With traditional 3-axis machining, you may need multiple setups to process a part with many faces. Five-axis technology completes the machining of contoured parts and other multi-sided parts in one structure. This enables you to manufacture components with complex geometries with fewer setups.

The additional rotation during this process helps you achieve more complex designs and geometries. The machine allows for seamless machining of arcs and angles that were previously only possible with multiple special fixtures. The 5-axis milling process can rotate a part to obtain the desired geometry in a single operation, eliminating the need for complex fixturing. Additionally, this technology pairs perfectly with GD&T annotation to generate datum features in a single operation. 5-axis milling is also suitable for CNC machining applications that require surface profile tolerances on complex contour surfaces.

The extra setup involved with manual machining compared to CNC machining causes the machinist to lose precise alignment during the manufacturing process. However, the minimal setup involved in 5-axis CNC milling reduces the potential for error and increases the precision required to achieve superior quality. The different types of 5-axis machines available today eliminate the need to reposition the workpiece at different angles during the machining process. Therefore, you can be sure of improved machining tolerances. Additionally, some machine configurations allow for the use of shorter cutting tools. This increases the tool life and ensures repeatability.

5-axis machining ensures that the cutting tool is tangential to the cutting surface. This arrangement allows more material to be removed each time the tool rotates. Thus, it reduces cycle time and overall machining costs.

The additional axes in this technology ensure the correct orientation of the workpieces, bringing them closer to the cutting tool. Therefore, you can use a shorter cutting tool to create the desired shape. These shorter tools can cut at very high speeds with little vibration. Less vibration further reduces the chance of "chatter" marks appearing on the finished product. Vertical machining also improves spindle utilization for machining angled surfaces. This way, you can achieve a better surface finish using this technology and reduce the cost and time associated with post-processing.

Due to the high speed of the process, 5-axis machined parts are often completed in a single operation. The single setup involved helps save time and money. Additionally, longer life and shorter cutting tools eliminate the need for frequent tool changes, saving money and time. Additionally, the 5-axis milling process can be automated, reducing manual operations and labor requirements. This reduces the labor costs associated with the process. Therefore, 5-axis CNC machining is a cost-effective solution to get your products to market faster.

Although 5-axis CNC technology has many advantages, its use is not suitable for some applications.

The cost of purchasing a 5-axis CNC machine and its basic software is high. It is much higher than what is needed for a 3-axis machining center. Likewise, the machine's maintenance requirements are more challenging than traditional machine tools. This aspect also directly increases the processing cost of 5-axis machined parts.

These two additional rotational motions and their spatial trajectories are abstract and complex. For example, to process freeform surfaces, you need to:

Through multiple coordinate transformations;

Perform complex spatial geometry operations;

Consider the coordination of the motion of each axis.

All of this is necessary to avoid collisions and interferences and to ensure the correct amount of interpolated motion. Therefore, it is more difficult to program to achieve the required machining accuracy, precision and surface quality.

5-axis CNC milling is an advanced technology that involves advanced programming, machine setup, and operation. Therefore, the process requires highly skilled technical operators. This often translates into increased labor costs.

Underutilization of 5-axis functionality is a common phenomenon. Some operators do not understand the full capabilities of the machine. Others may not have the programming knowledge for cutting-edge operations.

The following tips will help you take advantage of this manufacturing process:

Try to get enough information before deciding to use 5-axis technology. Analyze data received from customers and check for accuracy and correctness. Take a close look at the components and check if pre-testing is required. Simulation software will help validate the process before translating the CAD design into the CAM model. The software will help monitor tool length, interference and part dimensions. An investment in programs and software that complement the 5-axis machine capabilities is required. Additionally, it’s a good idea to perform a cost analysis to ensure you’re using the most cost-effective workflow.

Creating 5-axis toolpaths often involves the usual trade-off between high-speed cutting and reduced risk of collisions. A collision could result in broken components, damage to the machine, or cause you to scrap the part. Fortunately, this can be eliminated using certain software tools. The software program checks every movement of the tool ahead of time to see if it will encounter anything. As long as the CNC machining design is modeled correctly, the software will detect the collision before it occurs.

5-axis CNC machining ensures high productivity, but it can also increase the risk of errors. This could manifest as using the wrong tool or a damaged cutting tool. Using a tool detection system can minimize such errors. The system will help analyze the tools you want to use, ensuring you choose the right one.

Running dynamics will achieve the details of each function with greater accuracy. It will help you understand the correct positioning of the cutting tool relative to the axis turning point.

This manufacturing process is suitable for applications across multiple industries that require high precision, complex shapes and tight tolerances.

Typical applications are:

The aerospace industry requires parts with organic shapes, with contoured edges and compound shapes. Aerospace parts have unique and complex geometries, making 5-axis machining an ideal technology choice. This process achieves a high level of detail and reduces the need to re-fixture the cutting head. Therefore, parts for aerospace applications are kept as precise as possible and in compliance with industry standards.

When manufacturing medical devices, quality and precision cannot be compromised. The high-precision capabilities of 5-axis manufacturing processes facilitate the production of implants, devices, and other equipment to meet stringent healthcare requirements. Most components are small and complex. Others are sophisticated electronic scanning and monitoring equipment. 5-axis technology offers an efficient and cost-effective method for producing these components.

The energy industry often requires complex and advanced components, including solar power systems and power stations. The rapid emergence of 5-axis machining provides a guarantee for the CNC precision machining of refined and specialized parts of energy equipment. These parts are machined for durability and provide stability to the workspace.

Deciding between 5-axis machining centers and other technologies can be very challenging. There are many factors to consider to ensure you make the best choice. Here is a comparison between this technique and other methods.

Many people tend to confuse these two techniques. Five-axis CNC machining, also known as continuous five-axis machining, involves the continuous rotation of the tool along five axes. In contrast, 5+5 axis machining executes a 3-axis program. During this process, the tool is locked at a certain angle. The two axes of rotation determine this angle.

The main advantage of 5-axis over 3+2-axis CNC machining is speed. The latter involves constantly stopping and starting the machine between each tool orientation. However, the former completes the cutting in one go. In addition, 5-axis machining is more suitable for complex surfaces, while 3+2-axis CNC machining is mainly used for plane machining.

Since 5-axis machines require fewer fixtures and no special fixtures, the machining cost is lower than 3+2-axis machines. However, you should note that the programming involved with 5-axis technology is much more complex than 3+2-axis machining.

Unlike 5-axis CNC machining, 3D printing is an additive manufacturing process that builds components one layer at a time. While these technologies have different modes of operation, their applications have more overlap than not. They all offer high precision, fast turnaround, improved repeatability and excellent surface finish.

No special fixtures or tools are required for 3D printing. Therefore, the initial setup costs are also low. However, 5-axis CNC machines offer better dimensional accuracy than 3D printing. They can machine both small and large parts accurately. Obtaining extremely tight tolerances through 3D printing will require additional post-processing operations.

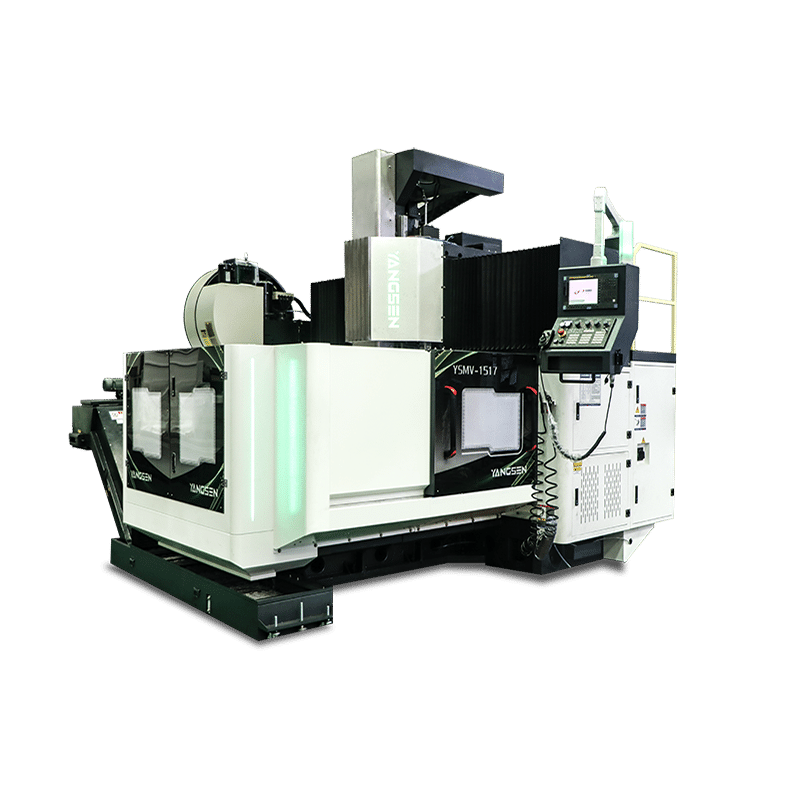

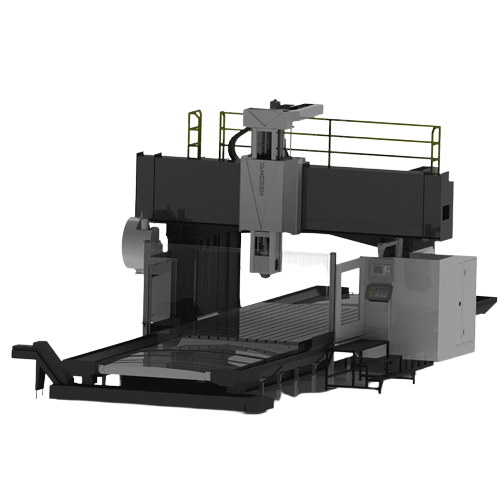

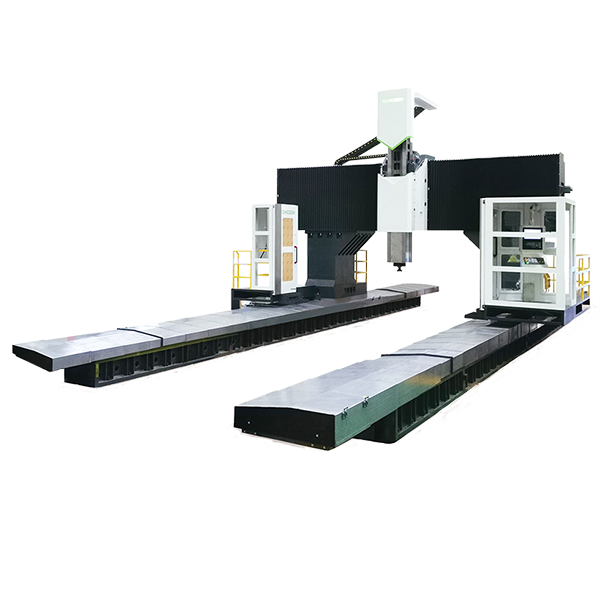

Yangsen is a leading CNC machining service provider with presence all over the world. We have several 5-axis CNC machines, including YSMT-6042, YSMV-3018, YS650-5AX, YSV-855, etc. Our powerful 5-axis CNC machining services can manufacture high-precision CNC machined parts with high quality, fast lead times, and competitive prices.

Our highly skilled technicians also provide technical support to help you choose between our processing technologies and production-grade materials. Contact us today so we can discuss your project.