Large gantry 5 axis CNC machine is heavy duty industrial CNC router machine used for trimming formed parts, molds, patterns, composites, automotive, large envelope parts, other 3D surface milling and 3D shape cutting projects.

Max. X-axis Travel :

5000mmMax. Y-axis Travel :

4300mmMax. Z-axis Travel :

1500mmMax Workpiece Length :

4600mmMax Workpieces Width :

3000mmMax Workpieces Weight :

53TApplication :

Medical IndustryProcessing :

Drilling, Tapping, Milling, Surface MillingYSMV-5041-5X Gantry CNC Machine Features

|

|

Large gantry 5 axis CNC machine is heavy duty industrial CNC router machine used for trimming formed parts, molds, patterns, composites, automotive, large envelope parts, other 3D surface milling and 3D shape cutting projects. The overall layout of the machine tool is a fixed-beam beam structure, and the worktable moves forward and backward; the left and right columns and the bed are distributed on both sides of the workbench. The gantry table moves forward and backward in the X axis, the square ram moves vertically in the Z direction on the slide plate, and the slide plate and the ram move horizontally in the Y direction on the beam. As shown below: (1) The workbench moves longitudinally (X axis) (2) The saddle moves along the beam (Y axis) (3) Axial movement of the ram (Z axis) |

1. Machine tool spindle

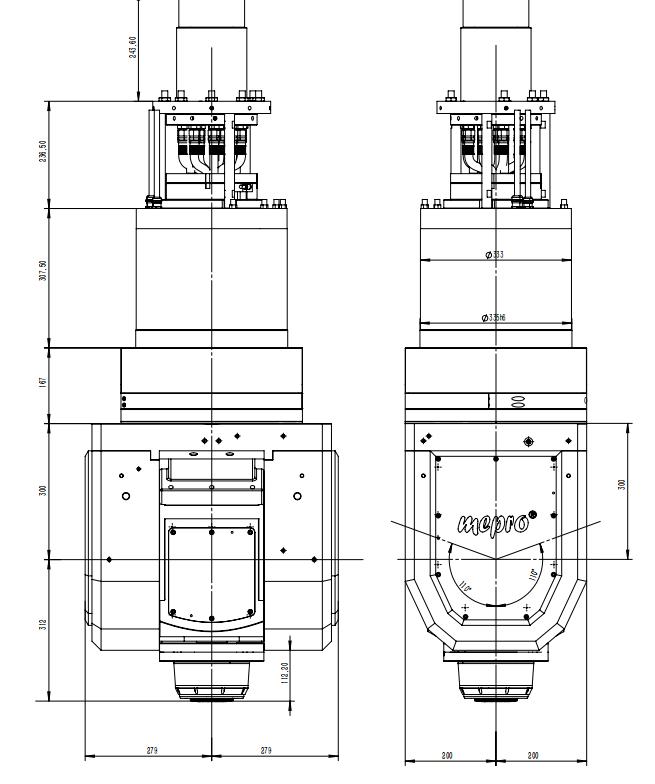

The spindle adopts HSKA63 high-speed electric spindle. The spindle has a water-cooled internal cooling method to reduce the thermal deformation of the spindle, improve the stability of the spindle precision and the machining accuracy of the machine tool. The machine tool has the functions of spindle orientation and rigid tapping. The headstock parts adopt double nitrogen liquid balance cylinder mechanism to ensure the stability of the headstock movement.

Five-axis linkage double pendulum milling head: A/C mechanical axis + electric spindle, fork-type integrated structure, with high rigidity characteristics, A/C axis is driven by a unique anti-backlash structure.

2. Feed transmission of each axis

The X, Y, and Z transmissions all use AC servo motors as power sources, and ball screws as transmission components. The ball screw is fixedly supported at both ends, supported by imported special precision bearings and pre-stretched in two directions to ensure the feed rigidity and life of the screw. The Y-axis screw is equipped with an advanced auxiliary support structure, which can effectively avoid the accuracy error caused by the sag of the center of gravity of the large-stroke screw. The Z-axis motor has an automatic brake function. In the event of a power failure, the automatic brake will hold the motor shaft tightly so that it cannot rotate.

3. Rail form

The X-axis guide rail pair adopts two heavy-duty linear guide rails, which have small friction coefficient and high sensitivity; small high-speed vibration and no crawling at low speed. The positioning accuracy of the drive shaft is high, and the servo drive performance is excellent; at the same time, the bearing capacity is large, and the cutting vibration resistance is good, which can improve the dynamic characteristics of the machine tool, improve the precision stability and service life of the machine tool;

The Y-axis beam guide pair adopts two heavy-duty linear guide rails; the guide rails are arranged in steps, with a large span, and sufficient bending rigidity and torsional rigidity.

The Z-axis guide rail pair adopts four heavy-duty linear guide rails to ensure smooth cutting during processing.

4. Basic parts of machine tools

The bed, columns, beams, and spindle boxes are all cast with high-strength cast iron materials and resin sand technology. In order to meet the heavy-duty cutting of the machine tool, the cross-beam adopts a large cross-section, which has sufficient bending rigidity and torsional rigidity. These large pieces are designed with computer-assisted three-dimensional software, and the arrangement of ribs is reasonable to improve the rigidity of the large pieces.

5. Machine tool lubrication

There are two types of lubrication for machine tools: grease lubrication and automatic thin oil lubrication.

Grease lubrication part: Three coordinate bearings

Automatic thin oil lubrication parts: ball screw pair, linear guide rail, cast iron-friction guide rail pair composed of plastic paste

Automatic thin oil lubrication is a timing and quantitative automatic method, the action is automatically controlled by the numerical control system, and can detect and alarm

6. Cutting cooling chip removal system

The cutting cooling of the machine tool adopts the external cooling method, and the cooling liquid is emulsified and non-corrosive liquid. The chip removal is sent to the trolley through the two-measuring chain plate chip removal machine on the bed.

7. Machine tool protection device

The bed guide rail (X-axis) of the machine tool adopts an anti-rust metal telescopic protective cover; the beam guide rail (Y-axis) adopts an organ-type protection; work in the environment.

8. Electrical system

This machine tool adopts German Siemens 840D/ONE CNC system. The spindle drive unit, feed drive unit, AC spindle motor, and AC feed servo motor are all imported, with advanced performance, stability and reliability.

Gantry Machining Center Parameters

| Subject | Specification | unit | YSMV-5041-5X |

| Travel | X/Y/Z axis | mm | 5000*4300*1500 |

| Spindle nose to the worktable surface | mm | 250-1750 | |

| Gantry width | mm | 4100 | |

| Gantry passable height | mm | 1780 | |

| Worktable | worktable(L*W) | mm | 4600*3000 |

| Worktable max load | t | 30 | |

| T SLOT | mm | 28×200 | |

| Spindle | Spindle, taper hole (model/installation size) | mm | HSKA63 |

| Spindle speed | rpm | 18000 | |

| Spindle delivery type | AC swing five-axis head | ||

| Feed | Feed rate (X/Y/Z ) | m/min | 2012-12-12 |

| The max cutting feed rate | mm/min | 6000 | |

| ATC(optional) | Tool change method | Side Mount | |

| Tool Holder specifications | type | HSKA63 | |

| Tool capacity | tools | 24 | |

| Maximum tool diameter (adjacent tool) | mm | 80 | |

| Maximum tool diameter (without adjacent tool) | mm | 120 | |

| Maximum tool length | mm | 350 | |

| Maximum tool weight | kg | 8 | |

| Fastest tool change time | sec | 2.5 | |

| Motor | Spindle motor | kw | 30 |

| x/y/z axis motor | kw | 5.4/5.4/5.4 | |

| Cutting water pump motor | m/h-m | 4-60 | |

| Accuracy GB/T 19362.2—2017 | Positioning | mm | 0.02/0.015/0.01(with grating scale) |

| Repeatability | mm | 0.01/0.008/0.005(with grating scale) | |

| Power requirement | Power requirements | kva | 40 |

| Air source requirements | Kg/cm² | 6^8 | |

| Others | L*W*H | mm | 12800*8050*6420 |

| Weight | t | About 53 |

Tags :