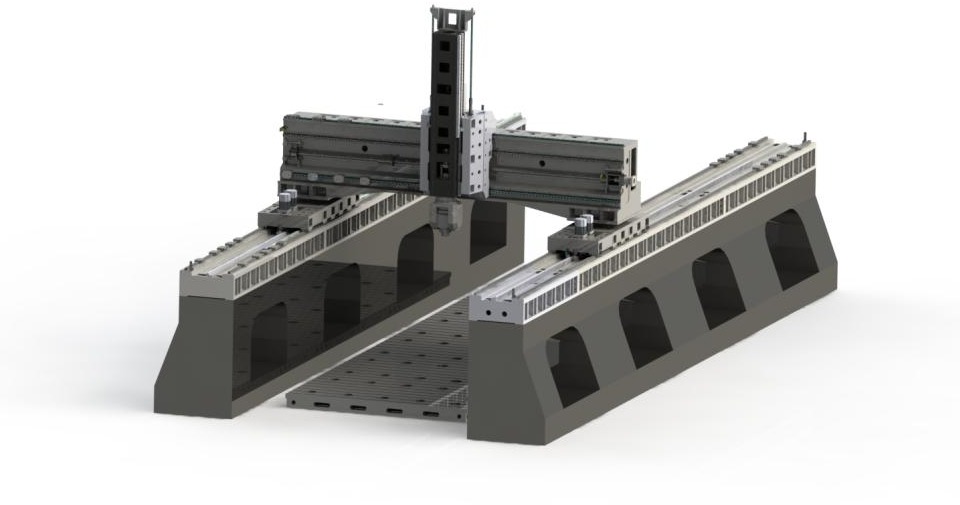

5-Axis Machine YSMT-6042-5X Gantry CNC Machining Center Planer Milling Machine

CNC machining centers are ideal for composite materials, aluminum, and metals processing. The advanced design of its structures, result of Yangsen Advanced Materials Technology’s continuous investments in research and development, and the sophisticated technological solutions adopted provide rigidity, precision over time, speed and flexibility,

Max. X-axis Travel :

6000mmMax. Y-axis Travel :

3000mmMax. Z-axis Travel :

1500mmMax Workpiece Length :

6000mmMax Workpieces Width :

3000mmMax Workpieces Weight :

82TApplication :

Medical IndustryProcessing :

Drilling, Tapping, Milling, Surface MillingYSMT-6042-5X Gantry CNC Machining Center

The overall layout of the machine tool is a synchronous moving overhead crane-type gantry structure, with a fixed workbench and the gantry crane moving forward and backward; the left and right columns and the bed are distributed on both sides of the workbench. The gantry crane moves forward and backward along the X-axis, and the "box in box" symmetrical crossbeam structure design.

The X-axis adopts double-sided single drive, that is, both the left and right slides are equipped with a set of dual-motor gear rack drive structure, which can effectively eliminate the transmission gap and improve the positioning accuracy and repeatability of the machine tool.

The Z-axis transmission uses an AC servo motor as the power source and a ball screw as the transmission component. The ball screw is fixedly supported at both ends, supported by imported special precision bearing groups and pre-stretched in both directions to ensure the screw feed stiffness and life. The Y-axis lead screw is equipped with an advanced auxiliary support structure, which can effectively avoid the precision error caused by the drooping center of gravity of the lead screw with a long stroke. The Z-axis motor has an automatic brake function. In the event of a power outage, the automatic brake will hold the motor shaft tightly to prevent it from rotating.

YSMT-6042-5X Gantry Machine Parameters

| Subject | Specification | unit | YSMT-6042-5A |

| Travel | X/Y/Z axis | mm | 6000*3000*1500 |

| Spindle nose to the worktable surface | mm | 350-1850 | |

| Gantry passable width | mm | 4200 | |

| Worktable | worktable(L*W) | mm | 6000*3000 |

| Worktable max load | t/㎡ | 10 | |

| T SLOT | mm | 36*200 | |

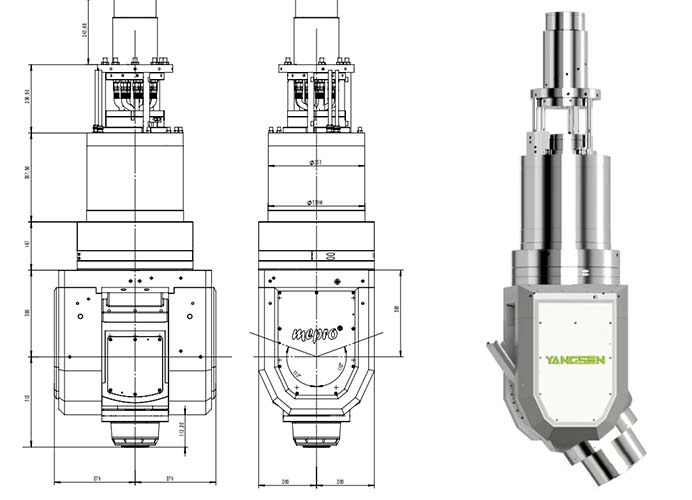

| Spindle | Spindle type | mm | HSKA63 |

| Spindle speed | rpm | 18000 | |

| Spindle delivery type | AC swing five-axis head | ||

| Feed rate | Feed rate ( X/Y/Z ) | m/min | 15/15/15 |

| The max cutting feed rate | mm/min | 6000 | |

| Motor | Spindle motor | kw | 30 |

| Three-axis servo motor | kw | 5.4*4/5.4/5.4 | |

| Cutting water pump motor | kw | 2.7 | |

| Accuracy(GB/T 19362.2-2017) | Positioning | mm | 0.03/0.02/0.015 |

| Repeatability | mm | 0.02/0.015/0.01 | |

| Power requirement | Power requirement | kva | 60 |

| Air pressure requirement | Kg/cm² | 6^8 | |

| Others | L*W*H | mm | Appr 13000*8130*5950 |

| Weight | T | 82 |

Tags :