The double column machining center is mainly used for the processing of large boxes, complex surface molds, large-shaped parts, and plate parts.

Max. X-axis Travel :

9000mmMax. Y-axis Travel :

3200mmMax. Z-axis Travel :

1000mmMax Workpiece Length :

8800mmMax Workpieces Width :

2600mmMax Workpieces Weight :

30TApplication :

Medical IndustryProcessing :

Drilling, Tapping, Milling, Surface MillingCNC gantry machining center is with frame structure, with a grinding sliding guide, according to good rigidity, strong shock absorption, processing a wide range of good stability, the machine with milling, boring, drilling (drilling, expansion, hinge), tapping, Countersink and other processing functions, can be equipped with a variety of accessories milling head, with manual change function, to expand the processing range of the machine, parts can be completed at the same time a number of processing steps.

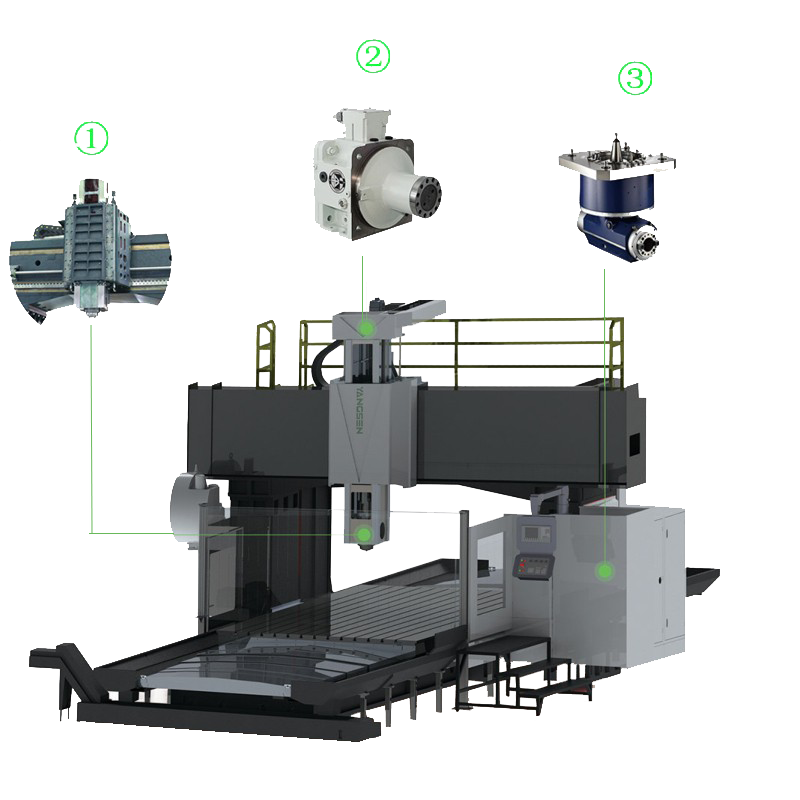

Square-Type Ram Gantry CNC Machine Structure Characteristics

① Square ram structure 500X500MM

The machine installs a four-sided restraint quenching guide guideway and double-cylinder nitrogen balance device. The overall rigidity is strong. It has the strong cutting ability and stable precision.

② Italy BF gearbox

High-performance speed, low noise, expandable motor constant power range with easy installation. It can be used in conjunction with multiple series of motors and adapt to high-strength tension.

③ Fully automatic side milling head

The transmission gear is a Gleason spiral bevel gear. The transmission is stable and accurate. It has a long service life. The internal transmission key of the milling head is a quenched part with minimal backlash.

Double-Column Machining Center Parameters

| Model | YSM-9032 | ||

| Subject | Specifications | Units | |

| Travel | X-Axis | mm | 9000 |

| Y-Axis | mm | 3200 | |

| Z-Axis | mm | 1000 (Optional 1250/1500) | |

| Spindle Nose to Worktable | mm | 350-1350 | |

| Three-Axis Guideway | X/Y Heavy Load Roller Linear Guideway Z-Axis Square-Type Ram | ||

| Door Width | 3200 | ||

| Type of Ram | Square-Type Ram (500x500) | ||

| Worktable | Worktable Size(L*W) | mm | 8800*2600 |

| Maximum Table Load | t | 30 | |

| T-Slot | mm | 13-28*200 | |

| Spindle | Spindle Type | type | BBT-50 |

| Spindle R.P.M. | rpm | 6000 | |

| Spindle Drive Type | DDS | ||

| Feedrate | Rapid Traverse (X/Y/Z) | m/min | 6/10/10 |

| Cutting Feedrate (X/Y/Z) | m/min | 6 | |

| Tool Changer | ATC | 24 (Option: 40/60) | |

| Motor | Spindle Motor | KW | 22/26 (140-286 Nm) |

| Three-Axis Servo Motor | KW | 6/3/3 (38/36/36 Nm) | |

| Accuracy | Accuracy | mm | 0.045/0.025/0.015 |

| Repeatability | mm | 0.03/0.02/0.01 | |

| Power Required | Power Requirement | kva | 60 |

| Air Pressure Requirement | kg/cm² | 6^8 | |

| Others | External Dimensions (L*W*H) | mm | 19600*6450*5820(6320) |

| Gross Weight | t | 76 | |

Standard Accessories

|

Spindle Coolant System Automatic Lubricating System Semi-Enclosed Guard |

Rigid Tapping Heat Exchange for Electric Cabinet Dual-Screw Type Chip Conveyor |

Dual LED Work Light LED 3 Color Warning Light Chain Type Chip Conveyor and Cart |

Geared Box Leveling Bolts and Pads M30 Auto Off |

Options

|

Optical Linear Scale CTS 20T/40T/60T ATC |

Workpieces Probe Chip Conveyor System Rotary Table |

Oil Mist System Oil Skimmer |

Manual/Semi-Auto 90Milling Head Auto Parts Probe Measuring System |

Tags :