Vertical CNC machining centers perform reliably and efficiently in manufacturing and production sectors of metal working across automotive, mechanical engineering, and medical technologies. From the universally applicable vertical versions to the 5 axis vertical machining centers, every machine has automatic tool changers and state-of-the-art CNC control technology.

Max. X-axis Travel :

800mmMax. Y-axis Travel :

450mmMax Workpiece Length :

800mmMax Workpieces Width :

700mmMax Workpieces Weight :

1000KGApplication :

Semiconductor IndustryProcessing :

Sliding, Milling |

High Efficiency

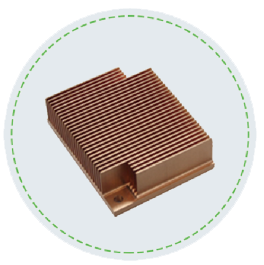

Special multi-station fixture: at least two mounting seats are fixed at the bottom of the shovel seat, and the shovel blades on each mounting seat respectively shovel the work piece fixed on the shoveling table, and the shovel blade can be obtained by shoveling at one time. Multiple heat sinks greatly improve the processing efficiency of the heat sink

High precision The blade seat, blade components, sliding table and supporting components are designed to be light and portable, which reduces the difficulty of their movements and improves the accuracy of their movements. Ensure the machining accuracy of shoveling metal parts. High Configuration Mitsubishi E80 CNC system, HG303 motor with 1:3 reducer, high torque; Japan THK 50mm diameter lead ballscrew, 45 wide roller linear guideway;The machine tool is equipped with name brand components,such as: Schneider Electric, Japanese SHOWA oil pump lubrication system, SMC pneumatic components. |

|

|

|

|

| PC series heat sink | Server heat sink | Power supply/LDE heat sink |

CPU heat sink |

Customized YSCP-835 Parameters

| Model | YSCP-835 | ||

| Subject | Specifications | Units | |

| Travel | X/Y/Z axis | mm | 800/4508 |

| Spindle Nose to Worktable | mm | 200-700 | |

| Spindle Center to Column | mm | 740 | |

| Three-Axis Guideway | / | Roller Linear Guideway | |

| Worktable | Worktable Size (L*W) | mm | 800X700 |

| Maximum Table Load | kg | 1000 | |

| Countertop bolt hole | mm | / | |

| T-Slot | mm | 5-18x120 | |

| Worktable Indexing | / | / | |

| Spindle | Spindle taper | type | / |

| Spindle speed | rpm | / | |

| Spindle Drive Type | / | Built-In | |

| Feedrate | Rapid Traverse (X/Y/Z) | m/min | 10/10 |

| Cutting Feedrate (X/Y/Z) | m/min | 10 | |

| Tool Changer | Automatic Tool Changer | / | / |

| Motor | Spindle Motor | kw | / |

| Three-Axis Servo Motor | kw | 3.0/3.0/3.0 | |

| Accuracy | Accuracy | mm | ±0.005 |

| Repeatability | mm | ±0.003 | |

| Power Required | Power Requirement | kva | 10 |

| Air Pressure Requirement | kg/cm² | 6^8 | |

| Others | External Dimensions (L*W*H) | mm | 3000*2500*2300 |

| Gross Weight | t | 5 | |

Standard Accessories

|

Safety Door Heat Exchange for Electric Cabinet Coolant Tank & Chip Tray |

Dual LED Work Light LED 3 Color Warning Light Air Gun |

Spindle Nose Air Blow Leveling Bolts and Pads Coolant Gun |

Automatic Lubricating System Fully Enclosure Guard M30 Auto Off |

Options

|

Optical Linear Scale Oil Skimmer |

Tool Breakage System Workpiece &Tool Probe |

Oil Mist Collector Arm Type Tool Changer |

CTS

|

Tags :