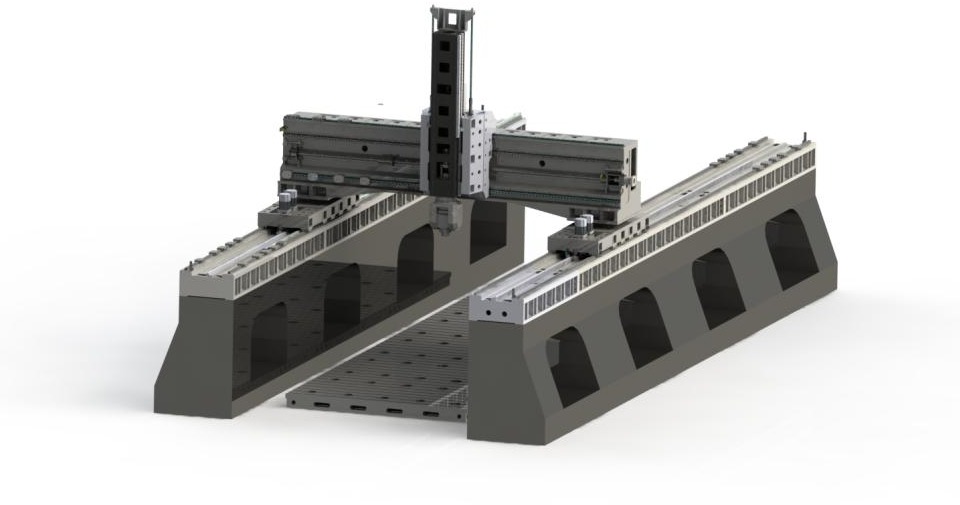

5-Axis Machining Center YSMD10052-5A Planer Milling Machine

The 5-axis Gantry milling center is a very large machine that allows machining operations on 5- axis and 5-sides to be carried out in one setup part clamping, from roughing to finishing. It is particularly suitable for large complex parts intended for machining molds, dies, stamping tools, models and precision parts. The choice of fixed Portal architecture makes it possible to offer a machine with maximum rigidity for extremely accurate machining in various and hard materials. The modular design and the many alternatives and equipment offered make it easy to meet all customer requirements.

Max. X-axis Travel :

10000mmMax. Y-axis Travel :

4000mmMax. Z-axis Travel :

2000mmMax Workpiece Length :

10000mmMax Workpieces Width :

3500mmMax Workpieces Weight :

102TApplication :

Medical IndustryProcessing :

Drilling, Tapping, Milling, Surface MillingYSMD10052-5A Planer Milling Machine Features

The overall layout of the machine tool is a synchronous moving crane type gantry structure, with the workbench fixed and the gantry crane moving forward and backward; the left and right columns and the bed are distributed on both sides of the workbench. The gantry crane moves forward and backward on the X-axis, and the "box-in-box" symmetrical beam structure design.

Application of YSMD10052-5A Planer Milling Machine

Gantry Double Column CNC Machine is ideal for machining large parts for heavy industries that require very complex structures and that not only extend to automobiles, boats, and airplanes but also to the manufacturing of other machine tools. And it is to manufacture some of the most used machines in workshops.

YSMD-10052-5A Gantry Machine Parameters

| Subject | Specification | unit | YSMD-10052-5A |

| Travel | X/Y/Z axis | mm | 10000*4000*2000 |

| Spindle nose to the worktable surface | mm | 500-2500 | |

| Gantry passable width | mm | 5200 | |

| Worktable | worktable(L*W) | mm | 10000*3500 |

| Worktable max load | t/㎡ | 10 | |

| T SLOT | mm | 28*200 | |

| Spindle | Spindle type | mm | HSKA63 |

| Spindle speed | rpm | 18000 | |

| Spindle delivery type | Electric spindle | ||

| Feed rate | Feed rate ( X/Y/Z ) | m/min | 30/30/30 |

| The max cutting feed rate | mm/min | 6000 | |

| Motor | Spindle motor | kw | 40 |

| Three-axis servo motor | kw | 5.2*4/5.2/5.2 | |

| Cutting water pump motor | kw | 2.7 | |

| ATC(optional) | Tool change method | Side Amount | |

| Tool handle specifications | type | HSKA63 | |

| Tool capacity | tools | 30 | |

| Maximum tool diameter (adjacent tool) | mm | 80 | |

| Maximum tool diameter (without adjacent tool) | mm | 120 | |

| Maximum tool length | mm | 350 | |

| Maximum tool weight | kg | 8 | |

| Fastest tool change time | sec | 2.5 | |

| Accuracy(GB/T 19362.2-2017) | Positioning | mm | 0.06/0.035/0.02 |

| Repeatability | mm | 0.045/0.025/0.015 | |

| Power requirement | Power requirement | kva | 60 |

| Air pressure requirement | Kg/cm² | 6^8 | |

| Others | L*W*H | mm | Appr 15300*8130*5950 |

| Weight | T | Appr 102 |

Tags :