CNC Vertical Milling Machining Center, CNC Double-Column Machining Center

The CNC gantry machining center is mainly suitable for parts processing in aviation automobile, energy, information, mold, and other industries. It has the characteristics of high speed, high precision, high flexibility, and environmental protection.

Max. X-axis Travel :

2000mmMax. Y-axis Travel :

2100mmMax. Z-axis Travel :

800mmMax Workpiece Length :

2000mmMax Workpieces Width :

1000mmMax Workpieces Weight :

3TApplication :

Medical IndustryProcessing :

Drilling, Tapping, Milling, Surface MillingYSMV-2013 Double Column CNC Gantry Machine

YSM-2013 series, the most popular bridge-type CNC milling machining center of Yangsen, have two models: one is X/Y-axis linear guideway, Z-axis box way, spindle speed is 6000rpm belt; another is a 3-axis linear way design with rapid traverse reaching 15 m / min and cutting feed rate reaching 15 m/ min, spindle speed is DDS / 12000RPM. Suitable for fine components machining and mold cutting. Its full casting structure provides long-term accuracy stability, and an ultra-wide column structure with a big dimension surface provides the best rigid support for the spindle and YZ axis.

1. Ultra-wide base of X axis with thick high rigidity table enhances table load capacity and ensures the best dynamic level accuracy.

2. The large stepped design of the Y axis makes guide ways close to the beam and spindle which effectively increases the rigidity of cutting load

3. Z-axis 15m rapid traverse, high acceleration/deceleration performance to achieve contour accuracy of high-speed mold machining.

4. Spindle and thermal compensation function for environmental temperature change can be chosen to ensure the accuracy change within 0.02mm which is influenced by environmental temperature change.

|

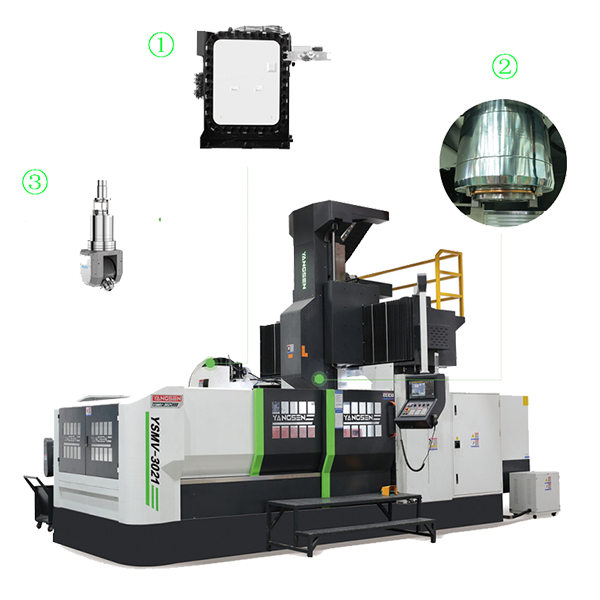

① Vertical and horizontal tool magazine

② Spindle Using BBT50- © 200 high rigidity spindle, 6 imported large steel ball bearings, super cutting ability.

③ Five-axis linkage double swing milling head AC axis torque motor + electric spindle fork-shaped integrated structure; AC axis installs torque motor structure; AC axis hydraulic holding for high-speed cutting and high rigidity. |

Double-Column Gantry CNC Machine Parameters

| Model | YSMV-2013 | ||

| Subject | Specifications | Units | |

| Travel | X-Axis | mm | 2000 |

| Y-Axis | mm | 2100 | |

| Z-Axis | mm | 800 | |

| Spindle Nose to Worktable | mm | 190-990 | |

| Three-Axis Guideway | X/Y/Z Heavy Load Roller Linear Guideway | ||

| Door Width | 1300 | ||

| Type of Ram | T-Type | ||

| Worktable | Worktable Size(L*W) | mm | 2000*1000 |

| Maximum Table Load | t | 3 | |

| T-Slot | mm | 7-22*140 | |

| Spindle | Spindle Type | type | BBT-50 |

| Spindle R.P.M. | rpm | 6000 | |

| Spindle Drive Type | Belt (DDS/Geared) | ||

| Feedrate | Rapid Traverse (X/Y/Z) | m/min | 15/15/15 |

| Cutting Feedrate (X/Y/Z) | m/min | 15 | |

| Tool Changer | ATC | 24 (Option: 40/60) | |

| Motor | Spindle Motor | KW | 15/18.5(143-236 Nm) |

| Three-Axis Servo Motor | KW | 3/3/3 (36 Nm) | |

| Accuracy | Accuracy | mm | 0.03/0.02/0.015 |

| Repeatability | mm | 0.018/0.015/0.01 | |

| Power Required | Power Requirement | kva | 45 |

| Air Pressure Requirement | kg/cm² | 6^8 | |

| Others | External Dimensions (L*W*H) | mm | 7600*3650*3550 |

| Gross Weight | t | 18 | |

Standard Accessories

|

Rigid Tapping Automatic Lubricating System Semi-Enclosed Guard |

Dual LED Work Light Heat Exchange for Electric Cabinet Dual-Screw Type Chip Conveyor |

Spindle Nose Air Blow LED 3 Color Warning Light Chain Type Chip Conveyor and Cart |

M30 Auto Off Leveling Bolts and Pads |

Options

|

Optical Linear Scale CTS 40T ATC |

Tool Breakage System Chip Conveyor System Rotary Table |

Oil Mist System Oil Skimmer 90° Manual Milling Head |

Air Conditioner Auto Parts Probe Measuring System 90° Auto Milling Head with AHC |

Tags :