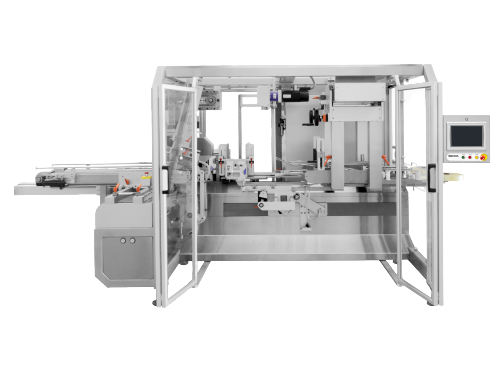

The CNC gantry machining center is mainly suitable for parts processing in aviation, automobile, energy, information, mold, and other industries. It has the characteristics of high speed, high precision, high flexibility, and environmental protection.

Max. X-axis Travel :

3000mmMax. Y-axis Travel :

2300mmMax. Z-axis Travel :

1000mmMax Workpiece Length :

3000mmMax Workpieces Width :

2000mmMax Workpieces Weight :

10TApplication :

Medical IndustryProcessing :

Drilling, Tapping, Milling, Surface MillingCNC Double Column YSM-3023 Machining Center

|

1. Applicable to all kinds of parts processing, mold processing, aluminum parts, and more. 2. X and Y axes use the roller-type linear guideway, and the Z axis offers a box way, it can be equipped with various types of manual attaching heads. 3. Designed with box ways with hand scrapping, cutting vibration adapting, and precise power transmission to get efficient, rigid, and accurate cutting. 4. Wide base with solid columns and beam, providing the best structure stiffness to ensure the best geometric accuracy of 3-axis travel. 5. Full casting components with guideways coated with precision scrapping to ensure the best stiffness and low friction. 6. One-piece casting for gear head transmission and headstock. Z-axis is at the symmetrical position of the spindle motor, offering accuracy and precision with micro-smooth movement. |

This gantry machining center can be widely used for large structural component industries for large molds, rail transits, engineering machinery, and wind power, etc.

YSM-3023 CNC Machining Center Parameters

|

Model |

YSM-3023 |

||

|

Subject |

Specifications |

Units |

|

|

Travel

|

X-Axis |

mm |

3000 |

|

Y-Axis |

mm |

2300 |

|

|

Z-Axis |

mm |

1000 |

|

|

Spindle Nose to Worktable |

mm |

280-1280 |

|

|

Three-Axis Guideway |

|

X/Y Heavy Load Roller Linear Guideway Z-Axis T-Type Ram Box Way |

|

|

Door Width |

|

2300 |

|

|

Worktable |

Worktable Size(L*W) |

mm |

3000*2000 |

|

Maximum Table Load |

t |

10 |

|

|

T-Slot |

mm |

9-28*200 |

|

|

Spindle |

Spindle Type |

type |

BBT-50 |

|

Spindle R.P.M. |

rpm |

6000 |

|

|

Spindle Drive Type |

|

Belt (DDS/Geared) |

|

|

Feedrate |

Rapid Traverse (X/Y/Z) |

m/min |

8/12/12 |

|

Cutting Feedrate (X/Y/Z) |

m/min |

8 |

|

|

Tool Changer |

ATC |

|

24 (Option: 40/60) |

|

Motor |

Spindle Motor |

KW |

15/18.5 (143-236 Nm) |

|

Three-Axis Servo Motor |

KW |

3/3/3 (36 Nm) |

|

|

Accuracy |

Accuracy |

mm |

0.03/0.02/0.015 |

|

Repeatability |

mm |

0.02/0.015/0.01 |

|

|

Power Required |

Power Requirement |

kva |

45 |

|

Air Pressure Requirement |

kg/cm2 |

6^8 |

|

|

Others |

External Dimensions (L*W*H) |

mm |

8800*5560*5600 |

|

Gross Weight |

t |

35 |

|

Gantry CNC Machine Sample Applications

|

|

|

|

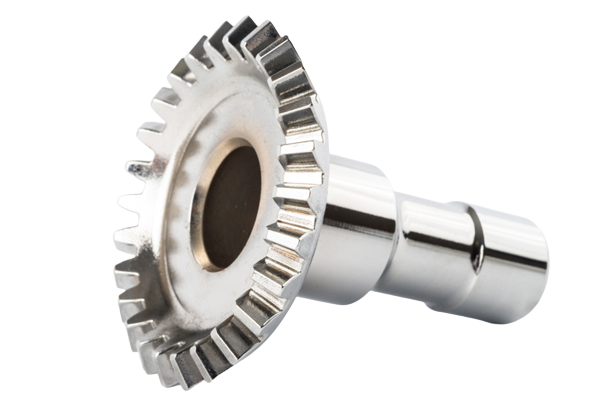

| Lathe | Turbocharger housing | Spiral bevel gear | Compressor |

Standard Accessories

|

Rigid Tapping Automatic Lubricating System Semi-Enclosed Guard |

Dual LED Work Light Heat Exchange for Electric Cabinet Dual-Screw Type Chip Conveyor |

Spindle Nose Air Blow LED 3 Color Warning Light Chain Type Chip Conveyor and Cart |

M30 Auto Off Leveling Bolts and Pads |

Options

|

Optical Linear Scale CTS 40T ATC |

Tool Breakage System Chip Conveyor System Rotary Table |

Oil Mist System Oil Skimmer 90° Manual Milling Head |

Air Conditioner Auto Parts Probe Measuring System 90° Auto Milling Head with AHC |

Tags :