The double-column machining center is made up of a structure manufactured and developed seeking great stability, as well as the elimination of stresses and deformations that could affect the parts to be machined. This type of machine tool works through computerized numerical control, which makes the equipment much faster and capable of producing large quantities of parts in series.

Max. X-axis Travel :

13000mmMax. Y-axis Travel :

4600mmMax. Z-axis Travel :

1500mmMax Workpiece Length :

12000mmMax Workpieces Width :

3500mmMax Workpieces Weight :

50TApplication :

Medical IndustryProcessing :

Drilling, Tapping, Milling, Surface MillingTraveling Double Column Machining Center

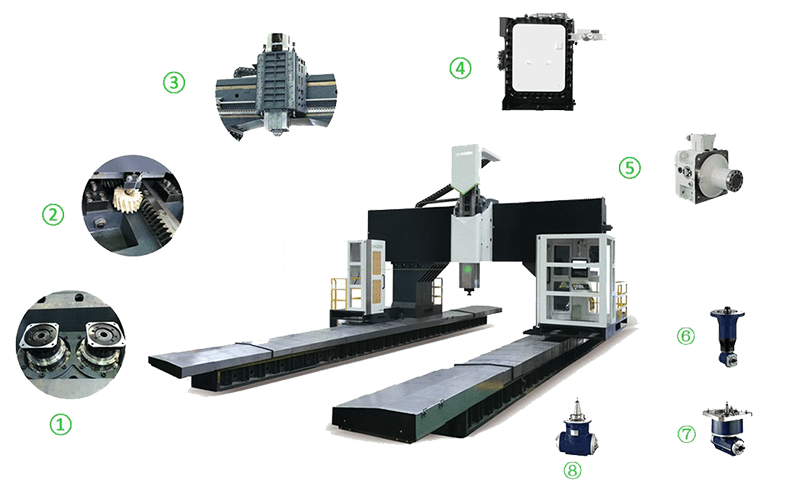

①. Dual Motor with Anti-Backlash Transmission Structure

High Precision, Heavy Load, High Speed, Low Noise, Longer Service Life.

②. Gear Transmission

High Precision, Heavy Load, High Speed, Low Noise, Longer Service Life.

③. Square Ram and Sliding Seat Structure

Dimension:500x500, Heavy-Duty Design;

Direct-Driven Design;

Large-Size and Heavy-Duty design ensures that the ram is firmly connected;

Three extended sliders at the top and four standard sliders at the bottom.

④. Vertical / Horizontal Automatic Tool Magazine

⑤. Italy BF Gear Box

High-performance speed, low noise. It could expand the motor's constant power range. It is easy to install. The machine can be used in conjunction with multiple series of motors. It can adapt to high-strength tension and small size.

⑥. Extended Angle Milling Head

⑦. Automatic Hydraulic Angle Milling Head

⑧. Two-Way Spindle Angle Milling Head

The traveling double-column machining center is a numerical control milling machine model specially designed by Vision Wide Tech for the demands of the precision large-scale mechanical equipment machining, power equipment, and transportation equipment machining industry with high positioning accuracy and heavy-duty cutting capability. A variety of AC head attachments is applicable for mold surface machining, and complex angular machining of various precise parts with high tangential velocity. With excellent tool tips point error automatic compensation function, automatically attached head and tool changing function can achieve full-automatic machining performance.

Machining Center Series Parameters

|

Model |

YSMD-12046 |

||

|

Subject |

Specifications |

Units |

|

|

Travel |

X-Axis |

mm |

13000 |

|

Y-Axis |

mm |

4600 |

|

|

Z-Axis |

mm |

1500 |

|

|

Spindle Nose to Worktable |

mm |

350-1850 |

|

|

Three-Axis Guideway |

|

X/Geared Transmission , Y/ Heavy Load Roller Linear Guideway, Z/T-Shape Slide |

|

|

Door Width |

|

4600 |

|

|

Type of Ram |

|

Square-Type Ram (500 * 500) |

|

|

Worktable |

Worktable Size(L*W) |

mm |

12000*3500 |

|

Maximum Table Load |

t |

50 |

|

|

T-Slot |

mm |

36*200 |

|

|

Spindle |

Spindle Type |

type |

BBT-50 |

|

Spindle R.P.M. |

rpm |

6000 |

|

|

Spindle Drive Type |

|

DDS |

|

|

Feedrate |

Rapid Traverse (X/Y/Z) |

m/min |

6/8/8 |

|

Cutting Feedrate (X/Y/Z) |

m/min |

6 |

|

|

Tool Changer |

ATC |

|

24 (Option: 40/60) |

|

Motor |

Spindle Motor |

KW |

17-42 |

|

Three-Axis Servo Motor |

KW |

5.2/5.2/5.2 |

|

|

Accuracy |

Accuracy |

mm |

0.06/0.035/0.02 |

|

Repeatability |

mm |

0.045/0.025/0.015 |

|

|

Power Required |

Power Requirement |

kva |

60 |

|

Air Pressure Requirement |

kg/cm² |

6^8 |

|

|

Others |

External Dimensions (L*W*H) |

mm |

16000x5860x5800 |

|

Gross Weight |

t |

128 |

|

Standard Accessories

|

Spindle Coolant System Automatic Lubricating System Semi-Enclosed Guard |

Rigid Tapping Heat Exchange for Electric Cabinet Dual-Screw Type Chip Conveyor |

Dual LED Work Light LED 3 Color Warning Light Chain Type Chip Conveyor and Cart |

Geared Box Leveling Bolts and Pads M30 Auto Off |

Options

|

Optical Linear Scale CTS 20T/40T/60T ATC |

Workpieces Probe Chip Conveyor System Rotary Table |

Oil Mist System Oil Skimmer |

Manual/Semi-Auto 90Milling Head Auto Parts Probe Measuring System |

Tags :