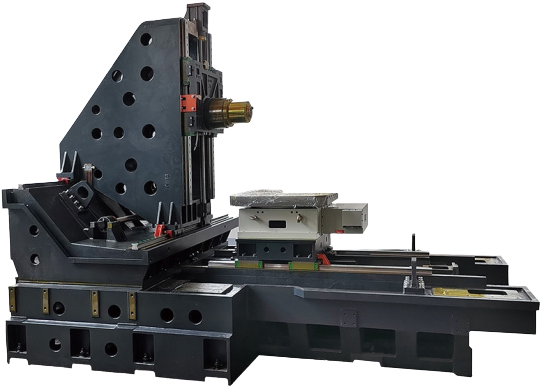

Horizontal CNC milling refers to CNC milling operations that utilize horizontal milling machines. As suggested by the name, the machines have horizontally oriented tooling — with rotating cylindrical cutters that can move along up to five axes to create the shapes, slots, details, and holes of a three-dimensional part. A horizontal machining center with a high-precision CNC turntable can realize one-time clamping, multi-process, multi-face and one-time machining.

Max. X-axis Travel :

1300mmMax. Y-axis Travel :

800mmMax. Z-axis Travel :

900mmMax Workpiece Length :

700mmMax Workpieces Width :

700mmMax Workpieces Weight :

1.2TApplication :

Auto PartsProcessing :

Surface Milling, Drilling Holes, TappingYSH-700D HMC Structure Characteristics

|

Horizontal CNC milling refers to CNC milling operations that utilize horizontal milling machines. With a high-precision CNC turntable, it can realize one-time clamping, multi-process, multi-face and one-time machining. This modern style of milling machine comes supported with a full system of additional features, such as automatic tool changers, carousels and magazines, coolant and cutting fluid systems, and specialty enclosures. This horizontal machining center installs a T design, worktable rotating structure form, ultra-wide guide guideway structure, the standard configuration of large torque, and high-speed motor. Our horizontal milling machines are suitable for processing various complex parts. |

Machine Cutting Performance

|

Surface Milling |

Steel 45# |

Drilling Holes |

Steel 45# |

Tapping |

Steel 45# |

|

Cutting depth 7mm |

|

Cutter diameter Ø82 |

|

Tapping M36 |

|

|

Cutter |

Ø120mm*5T |

Cutter |

Ø82mm*2T |

Cutter |

M36*3P |

|

Spindle speed |

420rpm |

Spindle speed |

500rpm |

Spindle speed |

120rpm |

|

Feed |

F500 |

Feed |

F100 |

Feed |

F480 |

|

Width |

100mm |

Width |

82mm |

Width |

36mm |

YSH-700D Horizontal Machining Product Characteristics

High Rigidity Structural Design, one-piece T-type base structure with rib construction for unprecedented rigidity;

Dual-wall column design for enhancing rigidity and durability;

Two X-axis guideways are positioned at different heights, stepped Design on X-axis to increase stable and reliable rapid axial movement;

The powerful spindle BBT50/190mm utilizes high-precision 6 pieces of ceramic ball bearings;

Servo motor driven reliable automatic tool magazine;

Automatic pallet change, 11-second pallet change servo motor driven.

|

Machine Bed, Column Equilateral triangle structure of the column, multi-layer stiffeners are arranged to improve the stability of the machine bed. Positive T structure bed, X-axis stepped layout, enlarged line guideway span, rigid support. Adopt a high-strength Rexroth roller guide, high load bearing, and stable precision. |

|

Spindle install 6 high-rigidity bearings; Outer diameter 190mm Taiwan original BBT50 spindle; Spindle air blow to prevent objects from entering the spindle; The spindle is equipped with ring spray to improve processing quality. The standard FANUC large-torque-wide-area motor ilP30/8000 is equipped with stronger heavy-cutting ability. |

|

Optical Linear Scales Optional Heidenhain, Fagor Optical Linear Scales, accuracy ± 5um, to ensure machine tool positioning accuracy. |

|

Double exchange table/ four-axis turntable Realize workpiece exchange and improve processing efficiency; The workpiece is placed outside for easy clamping; High rigidity alloy turbine, wear-resistant, high positioning accuracy; Heavy locking, reduces deformation, resistant to heavy cutting. |

|

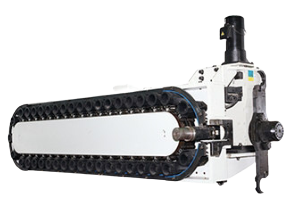

Tool magazine Using Taiwan imported frequency conversion tool magazine, tool change speed is fast and stable. |

YSH-700D Horizontal Machining Machine Parameters

| Model | YSH-700D | ||

| Subject | Specifications | Units | |

| Travel | X/Y/Z axis | mm | 1300/800/900 |

| Spindle Nose to Worktable | mm | 150-950 | |

| Spindle Center to Column | mm | 150-1050 | |

| Three-Axis Guideway | Roller Linear Guideway | ||

| Worktable | Worktable Size (L*W) | mm | 700x700*2 |

| Maximum Table Load | t | 1.2 | |

| Table Screw | mm | ||

| T-Slot | mm | 5-36x125 | |

| Number of Pallet | pcs | ||

| Table Indexing | 1°/0.001° | ||

| Maximum Turning Diameter | mm | φ1100 | |

| Spindle | Spindle Taper | type | BBT-50 |

| Spindle Speed | rpm | 8000 | |

| Spindle Drive Type | Belt | ||

| Feedrate | Rapid Traverse(X/Y/Z) | m/min | 40/40/30 |

| Cutting Feedrate(X/Y/Z) | m/min | 10 | |

| Tool Changer | Automatic Tool Changer | Chain Type (Servo Drive) | |

| Type of Tool Shank | type | BT-50 | |

| Tool Storage Capacity | Piece | 40 | |

| Max. Tool Diameter (Adjacent) | mm | 125 | |

| Max. Tool Diameter (Empty) | mm | 250 | |

| Max. Tool Length | mm | 350 | |

| Max. Tool Weight | kg | 25 | |

| Tool Change Time | sec | 4.2 | |

| Motor | Spindle Motor | kw | 15/18.5 |

| Three-Axis Servo Motor | kw | 3.0/3.0/3.0 | |

| Accuracy | Accuracy | mm | ±0.005 |

| Repeatability | mm | ±0.003 | |

| Power Required | Power Requirement | kva | 35 |

| Air Pressure Requirement | kg/cm² | 6^8 | |

| Others | External Dimensions (L*W*H) | mm | 7000*5265*3120 |

| Gross Weight | t | 21 | |

|

|

|

|

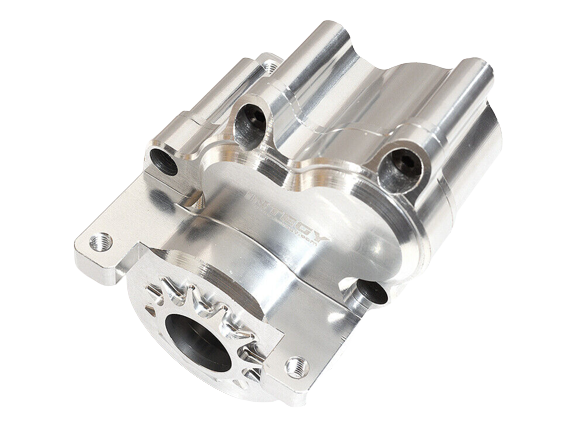

| cylinder block | pump body | Gear box housing | hydraulic control valve |

|

Arm Type Tool Changer

Automatic Lubricating System

Fully Enclosure Guard

|

Rigid Tapping

Heat Exchange for Electric Cabinet

Coolant Tank & Chip Tray

|

Daul LED Work Light

LED 3 Color Warning Light

M30 Auto Off

|

Spindle Nose Air Blow

Leveling Bolts and Pads

|

|

Optical Linear Scale

CTS

|

Tool Breakage System

Chain Type Chip Conveyor System

|

Oil Mist Collector

Oil Skimmer

|

Rotary Table

Workpiece &Tool Probe

|

Tags :