CNC vertical machining centers (VMC) remain machine shop staples. These milling machines have vertically oriented spindles that approach workpieces mounted on their table from above. vertical machining center (VMC) provides the features and performance you need at the best price, making it the best investment you’ve ever considered – providing utility, flexibility, productivity, and value.

Max. X-axis Travel :

1000mmMax. Y-axis Travel :

600mmMax. Z-axis Travel :

600mmMax Workpiece Length :

1300mmMax Workpieces Width :

600mmMax Workpieces Weight :

800KGApplication :

Auto PartsProcessing :

Surface Milling, Drilling Holes, Tapping, ScrapingVertical Machining Structural Characteristics:

|

CNC vertical machining centers (VMC) remain machine shop staples. These milling machines have vertically oriented spindles that approach workpieces mounted on their table from above. vertical machining center (VMC) provides the features and performance you need at the best price, making it the best investment you’ve ever considered – providing utility, flexibility, productivity, and value. |

Machine Cutting Performance:

|

Surface Milling |

Steel 45# |

Drilling Holes |

Steel 45# |

Tapping |

Steel 45# |

||

|

Cutting 6mm |

|

Cutter diameter Ø80 |

|

Cutting Tapping M30 |

|

||

|

Cutter |

Ø63mm*5T |

Cutter |

Ø80mm*2T |

Cutter |

M30*3P |

||

|

Spindle speed |

550rpm |

Spindle speed |

800rpm |

Spindle speed |

120rpm |

||

|

Feed |

F500 |

Feed |

F100 |

Feed |

F420 |

||

|

Width |

80mm |

Width |

80mm |

Width |

50mm |

||

Vertical Frame Machine Structural Characteristics

|

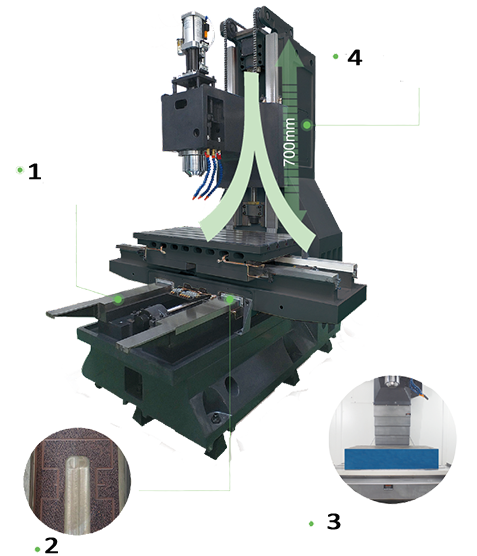

The bed is made of H300 cast iron, quenched, and all slide surfaces are precisely polished and covered with imported wear-resistant leather TURCITE-B. Ensure the accuracy and durability of the machine tool. 1. The wide and thick guide guideways ensure the stability of the machine tool during processing. 2. Scraping process 3. Each box-way type machine is subjected to load aging, and laser ballbar tests before leaving the plant. 4. T-shaped column design, the ultra-wide base for maximum rigidity with Z-axis traof 700mm. |

Application of Vertical Machining Frame Structural Characteristics

1. Mould

In the past, the production of molds was mostly manual, and it was necessary to use plaster to make a model, and then use a billet to make a model. Plane and grind it with a planer, and then use a hand or engraving machine to carve the shape of the product mold from the template.

2. Box Shaped Parts

Parts with complex shapes, cavities inside, large volumes, and more than one hole system, and the length, width, and height of the internal cavity with a certain proportion are suitable for CNC machining of the machining center.

3. Complex Surfaces

The machining center can be clamped at one time to complete the processing of all sides and top surfaces except the clamping surface. The processing principle is different for different models. The spindle or worktable can complete the 90° rotation with the workpiece. Therefore, the machining center is suitable for processing mobile phone parts, and auto parts.

4. Special Shaped Parts

The machining center can be assembled and clamped and can complete various processes such as drilling, milling, boring, expanding, reaming, and rigid tapping.

5. Discs, Sets, and Plate Parts

According to different main shaft transportation methods, the machining center has a distributed hole system with a keyway, radial hole or end face, a disk sleeve or shaft parts with a curved surface, such as a shaft sleeve with a flange, and a shaft part with a keyway or square head and more.

Vertical Machining Frame Structural Characteristics

| Model | YSP-1060 | ||

| Subject | Specifications | Units | |

| Travel | X/Y/Z axis | mm | 1100/600/600 |

| Spindle Nose to Worktable | mm | 180-780 | |

| Spindle Center to Column | mm | 655 | |

| Three-Axis Guideway | / | Box Way (Captain Turcite) | |

| Worktable | Worktable Size (L*W) | mm | 1300600 |

| Maximum Table Load | kg | 800 | |

| T-Slot | mm | 5-18x120 | |

| Spindle | Spindle taper | type | BBT-40 |

| Spindle speed | rpm | 8000 | |

| Spindle Drive Type | / | Belt | |

| Feedrate | Rapid Traverse(X/Y/Z) | m/min | 15/15/12 |

| Cutting Feedrate(X/Y/Z) | m/min | 10 | |

| Tool Changer | Automatic fool Changer | / | ARM Type |

| Type of Tool Shank | type | BT-40 | |

| Tool Storage Capacity | Piece | 24 | |

| Max. Tool Diameter (Adjacent) | mm | 80 | |

| Max. Tool Diameter (Empty) | mm | 120 | |

| Max. Tool Length | mm | 300 | |

| Max. Tool Weight | kg | 7 | |

| Tool Change Time | sec | 1.4 | |

| Motor | Spindle Motor | kw | 15 |

| Three-Axis Servo Motor | kw | 2.0/2.0/3.0 | |

| Accuracy | Accuracy | mm | ±0.01 |

| Repeatability | mm | ±0.005 | |

| Power Required | Power Requirement | kva | 20 |

| Air Pressure Requirement | kg/cm² | 6^8 | |

| Others | External Dimensions (L*W*H) | mm | 3300*2600*2800 |

| Gross Weight | t | 8.5 | |

Standard Accessories

|

Safety Door Automatic Lubricating System Fully Enclosure Guard Air Gun |

Dual LED Work Light Heat Exchange for Electric Cabinet Spindle Coolant Nozzles Coolant Gun |

Daul LED Work Light LED 3 Color Warning Light Coolant Tank & Chip Tray Tool Box |

Spindle Nose Air Blow Leveling Bolts and Pads M30 Auto Off

|

Options

|

Optical Linear Scale Oil Skimmer Workpiece & Tool Probe |

Tool Breakage System Chip Conveyor System Umbrella Type Auto Tool Changer (16/20) |

Oil Mist Collector Oil Skimmer Rotary Worktable (4Th-Axis) |

10000rpm DDS Spindle 12000rpm DDS Spindle Arm Type Tool Changer

|

Tags :