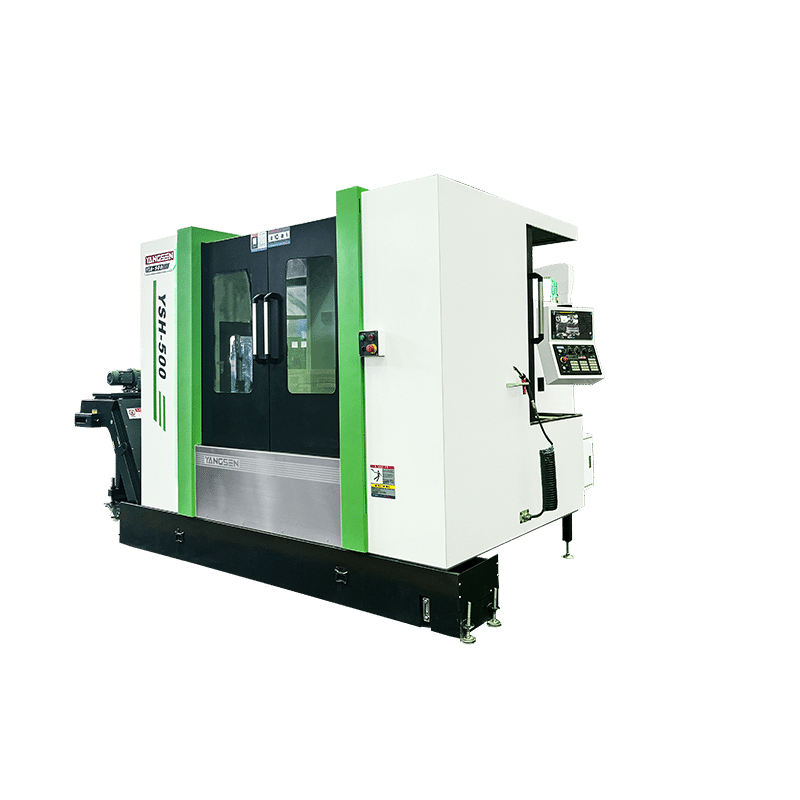

A horizontal machining center (HMC) is a machining center with its spindle in a horizontal orientation. This machining center design favors uninterrupted production work. One reason for this is that the horizontal orientation encourages chips to fall away, so they don't have to be cleared from the table. Our HMCs cut down operating costs by decreasing the number of damaged parts produced, increasing the repeatability, and accomplishing the most precise cuts with the assistance of rapid tool change-out.

Max. X-axis Travel :

1100mmMax. Y-axis Travel :

800mmMax. Z-axis Travel :

600mmMax Workpiece Length :

500mmMax Workpieces Width :

500mmMax Workpieces Weight :

0.4TApplication :

Auto PartsProcessing :

Surface Milling, Drilling Holes, TappingYSH-500 High Precision Horizontal Machining Center

|

1. The X/Y/Z axis adopts high-strength high-speed linear roller guide rails, and the rapid feed can reach 36/36/36 (m/min); the guide rails of each axis adopt imported heavy-duty roller linear guide rails, and the preload is V3 Class, high load, stable precision; 2. The spindle motor is equipped with βiI12/12000 high-torque generalized motor as standard. The outer diameter is up to 150mm and the high rigidity Taiwan spindle has a unique labyrinth device and labyrinth blowing device at the nose of the spindle to effectively protect the spindle. The maximum speed of the spindle can reach 15000rpm, which has the characteristics of high rigidity and high precision; 3. Machine tool parts belong to famous brands of famous factories, with top-level configuration in the industry. |

Machine Cutting Performance

|

Surface Milling |

Steel 45# |

Drilling Holes |

Steel 45# |

Tapping |

Steel 45# |

|

Cutting depth 7mm |

|

Cutter diameter Ø82 |

|

Tapping M36 |

|

|

Cutter |

Ø120mm*5T |

Cutter |

Ø68mm*2T |

Cutter |

M24*3P |

|

Spindle speed |

560rpm |

Spindle speed |

680rpm |

Spindle speed |

200rpm |

|

Feed |

F500 |

Feed |

F80 |

Feed |

F600 |

|

Width |

80mm |

Width |

68mm |

Width |

24mm |

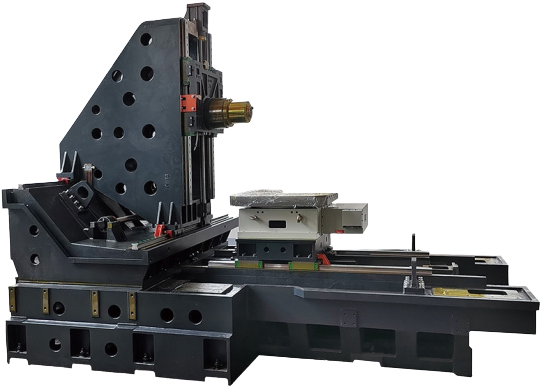

YSH-500D Horizontal Machining Product Characteristics

High Rigidity Structural Design, one-piece T-type base structure with rib construction for unprecedented rigidity;

Dual-wall column design for enhancing rigidity and durability;

Two X-axis guideways are positioned at different heights, stepped Design on X-axis to increase stable and reliable rapid axial movement;

The powerful spindle BBT50/190mm utilizes high-precision 6 pieces of ceramic ball bearings;

Servo motor driven reliable automatic tool magazine;

Automatic pallet change, 11-second pallet change servo motor driven.

|

Machine Bed, Column Equilateral triangle structure of the column, multi-layer stiffeners are arranged to improve the stability of the machine bed. Positive T structure bed, X-axis stepped layout, enlarged line guideway span, rigid support. Adopt a high-strength Rexroth roller guide, high load bearing, and stable precision. |

|

Spindle install 6 high-rigidity bearings; Outer diameter 190mm Taiwan original BBT50 spindle; Spindle air blow to prevent objects from entering the spindle; The spindle is equipped with ring spray to improve processing quality. The standard FANUC large-torque-wide-area motor ilP30/8000 is equipped with stronger heavy-cutting ability. |

|

Optical Linear Scales Optional Heidenhain, Fagor Optical Linear Scales, accuracy ± 5um, to ensure machine tool positioning accuracy. |

|

Double exchange table/ four-axis turntable Realize workpiece exchange and improve processing efficiency; The workpiece is placed outside for easy clamping; High rigidity alloy turbine, wear-resistant, high positioning accuracy; Heavy locking, reduces deformation, resistant to heavy cutting. |

|

Tool magazine Using Taiwan imported frequency conversion tool magazine, tool change speed is fast and stable. |

YSH-500D Horizontal Machining Machine Parameters

| Items | Specification | Units | YSH-500D |

| Travel | X/Y/Z Axis | mm | 1100/800/600 |

| X/Y/Z Axis | mm | 100-700 | |

| Spindle Center to Worktable | mm | -980 | |

| Spindle Nose to table Center | Roller Linear Guideway | ||

| Three-Axis Guideway | mm | ¢900mm | |

| Worktable | Table Size (L*W) | mm | 500*500-2 |

| The Max. Load Capacity Of The Workbench | kg | 400 | |

| Table Indexing | No/mm | 1°*360 | |

| Spindle | Spindle Taper Hole (Model/Installation Size) | mm | BBT40 |

| Spindle Speed | rpm | 15000 | |

| Spindle motor maximum speed | rpm | 12000 | |

| Spindle Drive Mode | Direct Connection | ||

| Feedrate | X/Y/Z Axis Rapid Feed | m/min | 36/36/36 |

| Cutting Feed | mm/min | 10000 | |

| Tool Changer | Tool Change Method | ARM Type (Servo Drive) | |

| Handle Specifications | type | BT40 | |

| Tool Capacity | tools | 24 | |

| Max. Tool Diameter (Adjacent Tool) | mm | 80 | |

| Max. Tool Diameter (Without Adjacent Tool) | mm | 120 | |

| Tool Length | mm | 300 | |

| Fastest Tool Change Time | sec | 1.8 | |

| Motor | Spindle Motor | kw | βiII12/12000 |

| Three Axis Servo Motor + B Axis | kw | βiS22/3000+βiS22B/3000+ | |

| βiS22/3000+βiS22/2000 | |||

| Cutting Water Pump Motor | m/h-m | 4-60 | |

| Accuracy | Positioning Accuracy | mm | ±0.005 |

| Repeatability | mm | ±0.003 | |

| Power Required | Power Requirements | kva | 30 |

| Air Source Requirements | Kg/cm | 6~8 | |

| External Dimensions | Length*Width*Height | mm | 5120*3560*3212 |

| Weight | t | 10 |

|

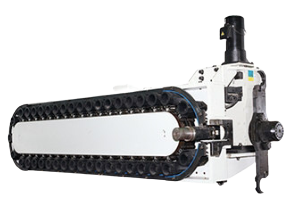

Arm Type Tool Changer

Automatic Lubricating System

Fully Enclosure Guard

|

Rigid Tapping

Heat Exchange for Electric Cabinet

Coolant Tank & Chip Tray

|

Daul LED Work Light

LED 3 Color Warning Light

M30 Auto Off

|

Spindle Nose Air Blow

Leveling Bolts and Pads

|

|

Optical Linear Scale

CTS

|

Tool Breakage System

Chain Type Chip Conveyor System

|

Oil Mist Collector

Oil Skimmer

|

Rotary Table

Workpiece &Tool Probe

|

Tags :