The machine tool of this product is equipped with name-brand components in the industry. It comes with high torque and a high-speed motor. With a super rigid bed design. It takes into account large torque, high speed, and high precision. It is suitable for high-speed precision machining in small and medium-sized mechanical parts in the automotive, textile machinery, and other industries.

Max. X-axis Travel :

1200mmMax. Y-axis Travel :

280mmMax. Z-axis Travel :

280mmMax Workpiece Length :

1320mmMax Workpieces Width :

650mmMax Workpieces Weight :

1200KGApplication :

Precision Mold, Auto PartsProcessing :

Surface Milling, Drilling Holes, TappingVertical Machining Structural Characteristics

|

The machine tool of this product is equipped with name brand components in the industry, equipped with a large torque, high speed motor and a super rigid bed design.

Taking into account high torque, high speed and high precision, it is suitable for processing all kinds of products and molds. |

Machine Cutting Performance

|

Surface Milling |

Steel 45# |

Drilling Holes |

Steel 45# |

Tapping |

Steel 45# |

||

|

Cuttin 6mm |

|

Cutter diameter Ø80 |

|

Cutting Tapping M30 |

|

||

|

Cutter |

Ø125mm*5T |

Cutter |

Ø80mm*2T |

Cutter |

M30*3P |

||

|

Spindle speed |

550rpm |

Spindle speed |

80rpm |

Spindle speed |

120rpm |

||

|

Feed |

F500 |

Feed |

F100 |

Feed |

F420 |

||

|

Width |

80mm |

Width |

80mm |

Width |

50mm |

||

Vertical Frame Machine Structural Characteristics

|

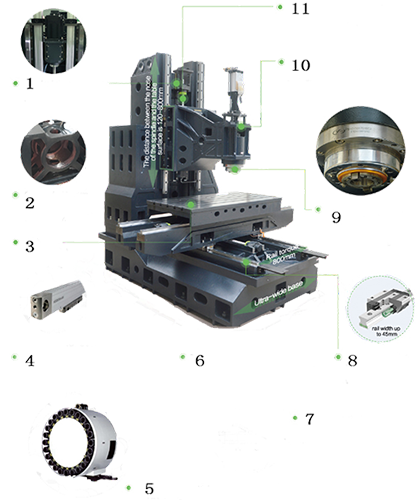

1. Standard air configuration device to ensure more stable processing. 2. Column double-arm structure, shoulder-type tool magazine design, better rigidity. 3. Worktable:1320*650 mm 4. Optical Linear Scales: Optional Heidenhain, Fagor grating optical linear scales, accuracy±5um, to ensure the positioning accuracy of the machine tool. 5. Taiwan servomotor tool magazine with tool change time of 1.4 sec. 6. Three-axis stroke X:1200 / Y: 680 / Z: 680 The reserved installation position of the Optical Linear Scales can be equipped with a coolant through ballscrew feature. 7. The spindle motor is equipped with a standard 15kW (SJ-D15-08) powerful spindle motor with a maximum speed of 8000rpm, suitable for heavy cutting. 8. Install Japanese THK or German Rexroth line guideways, linear guideway width up to 45mm. 9. Outer diameter 150mm high rigidity BBT40,10000r/min short nose spindle, spindle equipped with five bearings, coolant nozzles design. 10. The rear of the spindle head is a box-shaped design, triangular structure, Z-axis 6 sliding block support, and super rigidity. 11. Three-axis adopts Japanese THKΦ40-C3 grade screw, the three-axis adopts NSK original bearing (3062), 3+2 mode, pre-tensioning treatment to prevent thermal displacement

|

Vertical Machining Centers Parameters

| Model | YSV-1265 | ||

| Subject | Specifications | Units | |

| Travel | X/Y/Z axis | mm | 1200x680x680 |

| Spindle Nose to Worktable | mm | 120-800 | |

| Spindle Center to Column | mm | 700 | |

| Three-Axis Guideway | / | Roller Linear Guideway | |

| Worktable | Worktable Size (L*W) | mm | 1320x650 |

| Maximum Table Load | kg | 1200 | |

| T-Slot | mm | 5-18x100 | |

| Spindle | Spindle taper | type | BBT-40 |

| Spindle speed | rpm | 10000 | |

| Spindle Drive Type | / | Belt | |

| Feedrate | Rapid Traverse (X/Y/Z) | m/min | 30/30/30 |

| Cutting Feedrate (X/Y/Z) | m/min | 10 | |

| Tool Changer | Automatic Tool Changer | / | ARM Type |

| Type of Tool Shank | type | BT-40 | |

| Tool Storage Capacity | Piece | 24 | |

| Max. Tool Diameter (Adjacent) | mm | 80 | |

| Max. Tool Diameter (Empty) | mm | 120 | |

| Max. Tool Length | mm | 300 | |

| Max. Tool Weight | kg | 7 | |

| Tool Change Time | sec | 1.4 | |

| Motor | Spindle Motor | kw | 15 |

| Three-Axis Seixo Motor | kw | 3.0/3.0/4.5 | |

| Accuracy | Accuracy | mm | ±0.005 |

| Repeatability | mm | ±0.003 | |

| Power Required | Power Requirement | kva | 25 |

| Air Pressure Requirement | kg/cm² | 6^8 | |

| Others | External Dimensions (L*W*H) | mm | 3100x2558x2794 |

| Gross Weight | t | 8.7 | |

|

Safety Door Automatic Lubricating System Fully Enclosure Guard Air Gun |

Rigid Tapping Heat Exchange for Electric Cabinet Spindle Coolant Nozzles Coolant Gun |

Dual LED Work Light LED 3 Color Warning Light Coolant Tank & Chip Tray Tool Box |

Spindle Nose Air Blow Leveling Bolts and Pads M30 Auto Off Maintenance and Operational Manual |

Options

|

Optical Linear Scale CTS Workpiece & Tool Probe |

Coolant Gun Tool Breakage System Chip Conveyor System |

Oil Mist Collector Oil Skimmer Rotary Table |

12000rpm DDS Spindle 15000rpm DDS Spindle HSK-63-18000 Built-In Moto |

Tags :