Vertical machining centres can cut a wide variety of materials, lower production cycle times, reduce the cost of machining and increase the profitability of the process. The machine has been developed with great hindsight from the engineers to reduce the downtimes associated with frequent quality checks. CNC vertical machine is ergonomically designed in order to achieve enhanced operating conditions.

Max. X-axis Travel :

1100mmMax. Y-axis Travel :

600mmMax. Z-axis Travel :

600mmMax Workpiece Length :

1200mmMax Workpieces Width :

600mmMax Workpieces Weight :

1000KGApplication :

Precision Mold, Auto PartsProcessing :

Surface Milling, Drilling Holes, TappingVertical Machining Structural Characteristics

|

Vertical machining centres can cut a wide variety of materials, lower production cycle times, reduce the cost of machining and increase the profitability of the process. The machine has been developed with great hindsight from the engineers to reduce the downtimes associated with frequent quality checks. CNC vertical machine is ergonomically designed in order to achieve enhanced operating conditions. |

Machine Cutting Performance

|

Surface Milling |

Steel 45# |

Drilling Holes |

Steel 45# |

Tapping |

Steel 45# |

||

|

Cuttin 5mm |

|

Cutter diameter Ø60 |

|

Cutting Tapping M24 |

|

||

|

Cutter |

Ø125mm*5T |

Cutter |

Ø60mm*2T |

Cutter |

M24*3P |

||

|

Spindle speed |

1000rpm |

Spindle speed |

1200rpm |

Spindle speed |

150rpm |

||

|

Feed |

F600 |

Feed |

F100 |

Feed |

F450 |

||

|

Width |

56mm |

Width |

60mm |

Width |

40mm |

||

Vertical Frame Machine Structural Characteristics

|

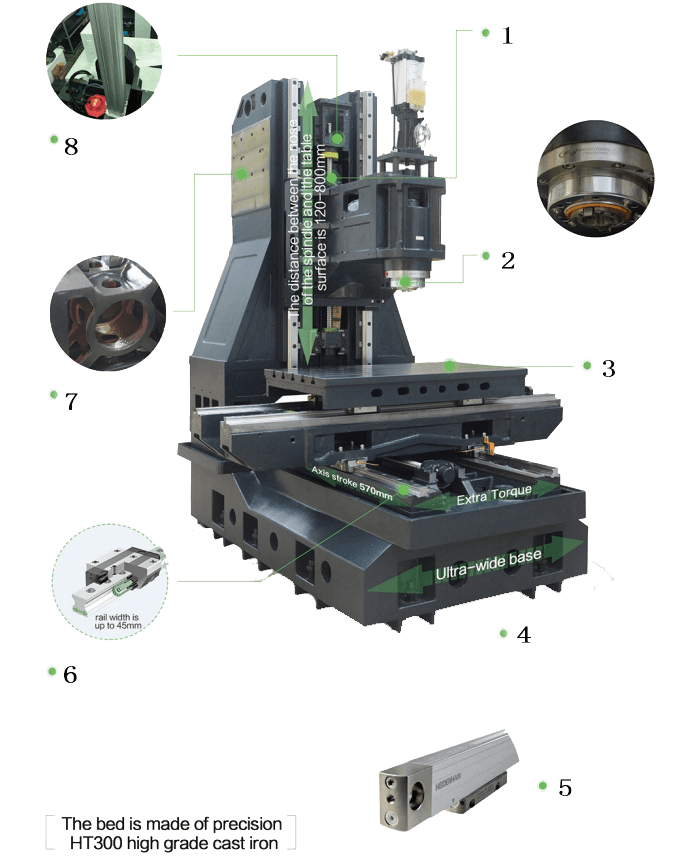

1. Three-axis adopts Japanese THKΦ40-C3 grade screw, three-axis adopts NSK original bearing (3062), 3+2 mode, pre-tensioning treatment to prevent thermal displacement. 2. BBT40 outer diameter 150mm high rigidity 10000rpm short nose spindle. It adopts 5 bearings, standard spindle coolant nozzles, and an optional HSK-63 electric spindle. 3. Worktable 1020*570 mm 4. Three-axis travel X:900/Y:570/Z:680. The reserved installation position of the Optical Linear Scales can be equipped with a hollow oil-cooled ballscrew. 5. Optical Linear Scales. Optional Heidenhain, Fagor optical linear scales, accuracy ±5um, to ensure the positioning accuracy of the machine tool. 6. It installs Japanese THK or German Rexroth linear guideway, the linear guideway width is up to 45mm. 7. Column double-layer arm structure, better rigidity. 8. Standard Air Counter Balance System processing is more stable. |

Vertical Machining Centers Parameters

| Model | YSV-1160 | ||

| Subject | Specifications | Units | |

| Travel | X/Y/Z axis | mm | 1100x600x600 |

| Spindle Nose to Worktable | mm | 120-720 | |

| Spindle Center to Column | mm | 650 | |

| Three-Axis Guideway | / | Roller Linear Guideway | |

| Worktable | Worktable Size (L*W) | mm | 1200x600 |

| Maximum Table Load | kg | 1000 | |

| T-Slot | mm | 5-18x100 | |

| Spindle | Spindle taper | type | BBT-40 |

| Spindle speed | rpm | 10000 | |

| Spindle Drive Type | / | Belt | |

| Feedrate | Rapid Traverse (X/Y/Z) | m/min | 30/30/30 |

| Cutting Feedrate (X/Y/Z) | m/min | 10 | |

| Tool Changer | Automatic Tool Changer | / | ARM Type |

| Type of Tool Shank | type | BT-40 | |

| Tool Storage Capacity | Piece | 24 | |

| Max. Tool Diameter (Adjacent) | mm | 80 | |

| Max. Tool Diameter (Empty) | mm | 120 | |

| Max. Tool Length | mm | 300 | |

| Max. Tool Weight | kg | 7 | |

| Tool Change Time | sec | 1.4 | |

| Motor | Spindle Motor | kw | 15 |

| Three-Axis Seixo Motor | kw | 3.0/3.0/4.5 | |

| Accuracy | Accuracy | mm | ±0.005 |

| Repeatability | mm | ±0.003 | |

| Power Required | Power Requirement | kva | 25 |

| Air Pressure Requirement | kg/cm² | 6^8 | |

| Others | External Dimensions (L*W*H) | mm | 2990X2484X2643 |

| Gross Weight | t | 7 | |

|

Safety Door Automatic Lubricating System Fully Enclosure Guard Air Gun |

Rigid Tapping Heat Exchange for Electric Cabinet Spindle Coolant Nozzles Coolant Gun |

Dual LED Work Light LED 3 Color Warning Light Coolant Tank & Chip Tray Tool Box |

Spindle Nose Air Blow Leveling Bolts and Pads M30 Auto Off Maintenance and Operational Manual |

Options

|

Optical Linear Scale CTS Workpiece & Tool Probe |

Coolant Gun Tool Breakage System Chip Conveyor System |

Oil Mist Collector Oil Skimmer Rotary Table |

12000rpm DDS Spindle 15000rpm DDS Spindle HSK-63-18000 Built-In Moto |

Tags :